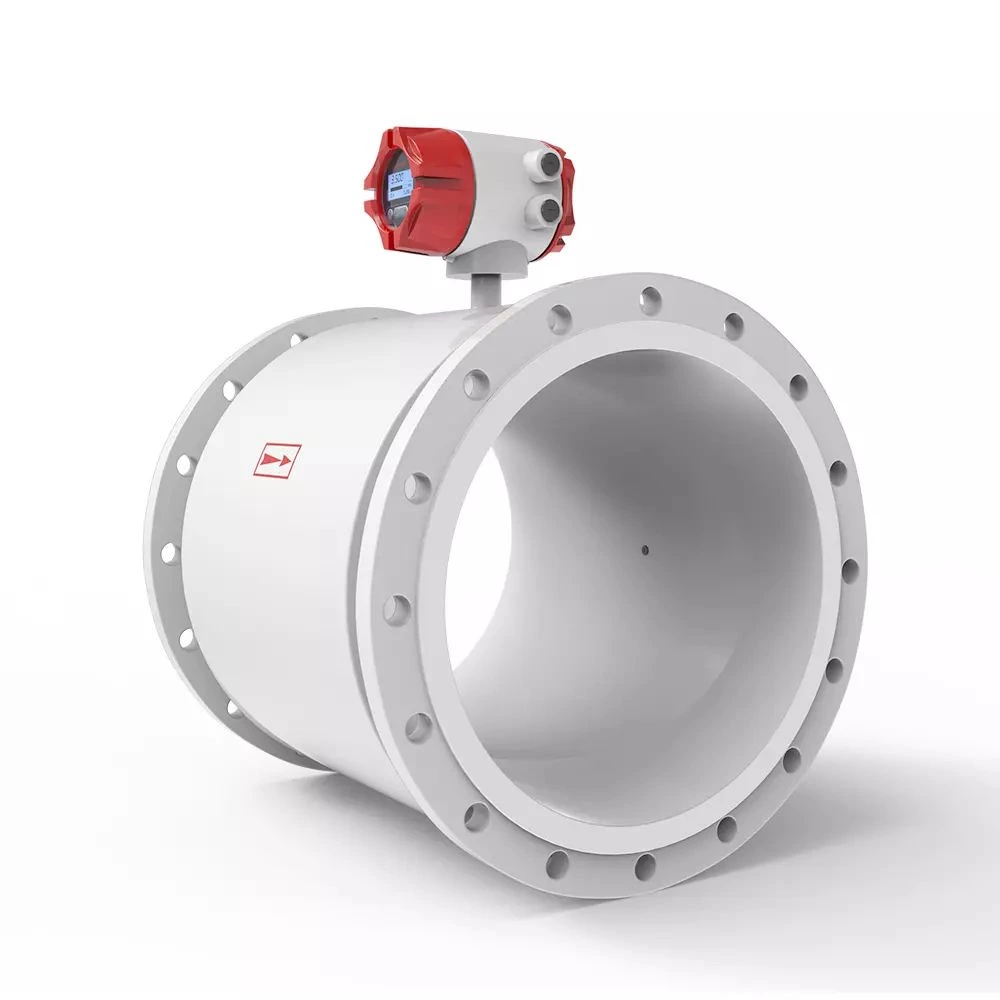

SIN-FMC400 Low Conductivity Electromagnetic Flow Meter

Accuracy: Measurement value±0.5%(Flow velocity 0.5m/s~5m/s)

Direct measured variables :Flow velocity

Calculated measured variables :Volume flow , mass flow

Velocity of flow:Typically Velocity of flow:0.5m/s~5m/s

Note:If there are differences in the selection of individual specifications, the label shall prevail, and high-voltage can be customized.

-

Specification

| Product | Electromagnetic flow meter |

| Model | SIN-FMC400 |

| Diameter nominal | DN10~DN1000 |

| Accuracy | Measurement value ±0.5%(Flow velocity 0.5m/s~5m/s) |

| Nominal pressure | DN10~DN250,PN<1.6MPa ; DN300~DN1000,PN<1.0MPa |

| Accuracy | Measurement value ±0.5%(Flow velocity 0.5m/s~5m/s) |

| Repetitiveness | 0.16% |

| Lining material | CR, UR, PTFE(F4), FEP(F46), and PTFE(PFA) |

| Electrode material | 316L Stainless Steel, Hastelloy C, Hastelloy B, Ti, Ta, Pt |

| Medium temperature | Chloroprene rubber(CR):-10℃~+70℃,Polyurethane rubber(UR):-10℃~+60℃,PTFE/FEP:-10℃~+120℃,PFA:-10℃~+120℃ |

| Power supply | AC:85V~245V,50Hz~60Hz; DC:22V~26V |

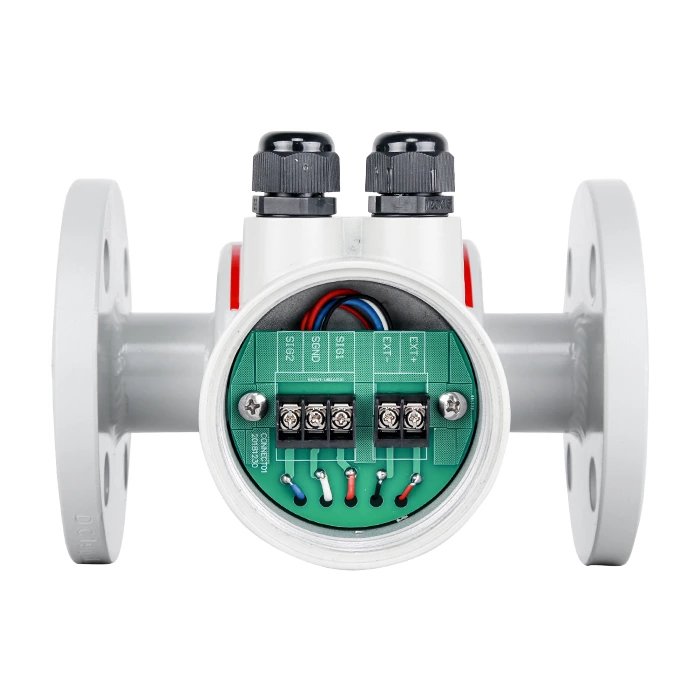

| Communications | RS485(MODBUS-RTU) |

| Ingress protection | IP65 |

-

Measuring principle

Mag meter works based on Faraday's law, when the liquid goes through the pipe at the flow rate of v with a diameter D, within which a magnetic flux density of B is created by an exciting coil, the following electromotive E is generated in proportion to flow speed v:

E=K×B×V×D

Where:

E-Induced electromotive force

K-Meter constant

B-Magnetic induction density

V-Average flow speed in cross-section of measuring tube

D-Inner diameter of measuring tube

The sensor uses the induced potential E as a flow signal and transmits it to the converter. After a series of digital processing by amplifying, transforming and filtering, the instantaneous flow and cumulative flow are displayed by a dot matrix liquid crystal with backlight.

-

Introduction

The electromagnetic flowmeter is designed based on the Faraday electromagnetic induction principle and are used to directly measure the flow rate of conductive liquids in closed pipelines. During on-site monitoring and display, standard current signals, pulse signals, and RS485 digital signals can be output for recording, adjustment, and control, achieving automatic detection and control. It can be widely used in industries such as tap water, chemical industry, coal, environmental protection, light textile, metallurgy, papermaking, etc.

-

Features

Reliable measurement, high accuracy, and good stability.

Integrated structure, no moving parts, easy to install, maintenance free.

RS485 communication interface - standard Modbus RTU protocol.

It is not affected by the direction of the fluid and can be accurately measured in both directions.

Adopting advanced low-frequency square wave excitation, zero point stability, strong anti-interference ability, and reliable operation.

The orientation of the header/display interface can be adjusted for easy reading.

Built in bilingual Chinese and English, allowing for free switching.

Suitable for measuring low conductivity media.

Suitable for slurry measurement.

Suitable for filling measurement.