Sinomeasure provides advanced measurement and monitoring solutions tailored for the textile and dyeing industry. Our instruments ensure accurate control of flow, level, pressure, and water quality throughout the production process.

From dye preparation and chemical dosing to wastewater management, Sinomeasure supports intelligent textile manufacturing, helping improve efficiency, reduce waste, and maintain consistent product quality.

Dye and chemical dosing control

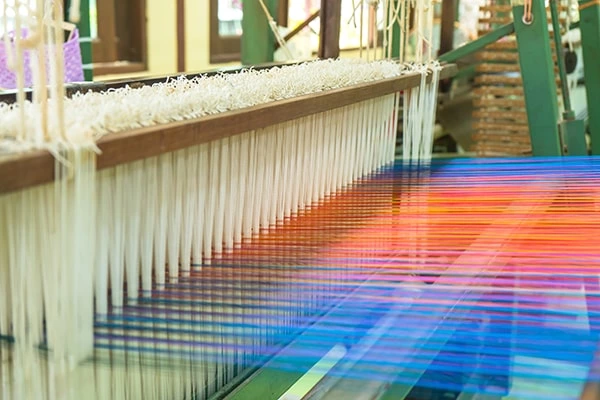

Circulation monitoring for washing and dyeing systems

Process water and wastewater management

Pressure and flow monitoring in textile production pipelines

Environmental and safety compliance monitoring

The challenge is accuracy across highly viscous, temperature-sensitive, and low-flow dyeing agents. The Coriolis mass flow meter is ideal, offering ±0.1% accuracy and the ability to measure viscosity independent mass flow. This ensures color repeatability (batch-to-batch consistency) and reduces material waste in critical batch processes.

The pH of the dye bath is paramount for color fastness and uptake. Self-cleaning pH electrodes with integrated PT1000 temperature compensation elements are recommended. This integrated design provides instantaneous temperature correction for the pH value, maintaining tight control over the chemical kinetics.

Magnetic flow meters (Magmeters) are excellent for water, but they must be rated for high temperatures. Alternatively, vortex flow meters provide a robust, reliable, and maintenance-free solution for utility streams and are frequently used for monitoring waste heat recovery systems.

During the rinsing process, conductivity sensors monitor the salt and chemical residue being washed out of the fabric. Rinsing can be terminated precisely when the conductivity reaches a preset low level, preventing excessive water usage and shortening the cycle time, leading to significant utility savings.

For smaller, high-value chemical tanks, guided wave radar (GWR) or capacitance level probes are highly accurate and immune to foam or vapor. They are preferred for inventory control of expensive dyes and auxiliaries.

A differential pressure (DP) transmitter or hydrostatic level transmitter with a chemical seal system is typically used. This arrangement isolates the sensor diaphragm from the hot, pressurized dye liquor, ensuring stable and accurate level measurement under dynamic conditions.

Conductivity (Specific and Cation) analyzers are essential. Low level conductivity monitoring ensures the feed water is sufficiently purified (low in dissolved solids), preventing scale buildup, corrosion, and catastrophic failure of boilers and heat exchangers.

Magnetic flow meters with PTFE or PFA liners and Tantalum electrodes are the most resistant to concentrated acids and bases, providing the necessary durability and accuracy for effluent treatment prior to discharge.

Sinomeasure has been dedicated to industrial process automation for decades, focusing on the research, development, and manufacturing of precision sensors and instruments. Our main products include water analysis instruments, recorders, pressure transmitters, flowmeters, and other field instruments used in a wide range of process industries.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.