Sinomeasure provides advanced measurement and control solutions to meet the demanding conditions of the chemical industry. Our instruments are designed for accuracy, durability, and safety — even in high-temperature, high-pressure, and corrosive environments.

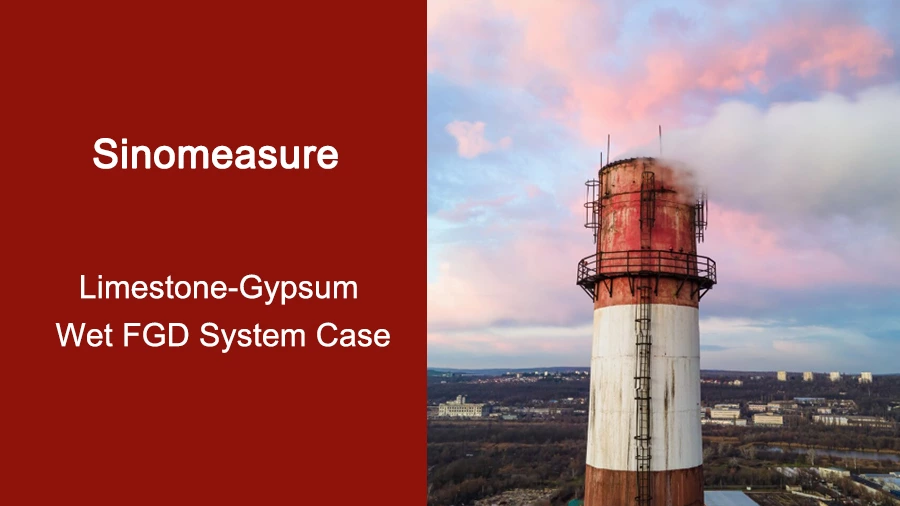

From raw material storage to reaction control and waste management, Sinomeasure ensures stable process performance and full compliance with industrial standards.

Chemical reaction and mixing process control

Acid, alkali, and solvent flow monitoring

Reactor pressure and level measurement

Cooling water and steam system management

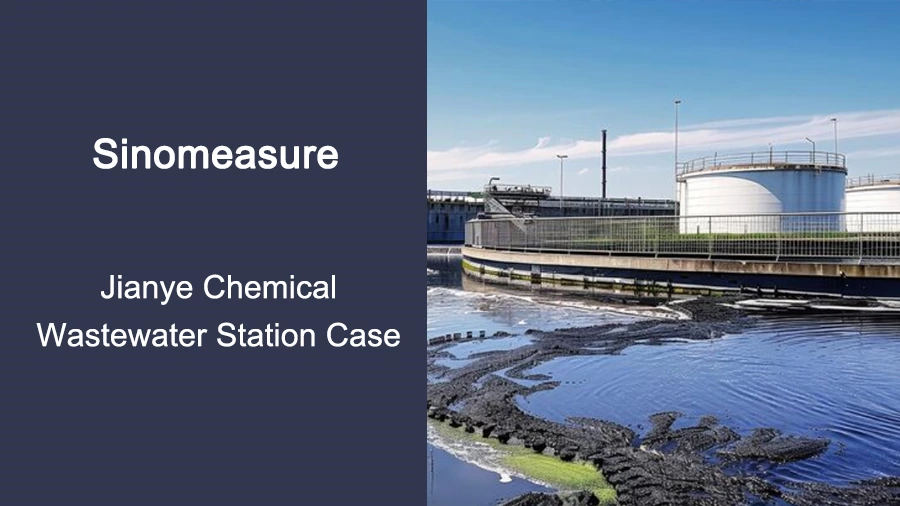

Effluent and wastewater analysis

Sensors must utilize advanced corrosion-resistant materials. For wetted parts in Pressure and Flow sensors, Hastelloy C, Tantalum, or non-metallic ceramic components are specified. For magmeters and pH probes, PFA/PTFE linings ensure instrument longevity, preserves calibration integrity, and prevents catastrophic failures.

Accurate mass balance relies on the Coriolis mass flow meter. By directly measuring mass flow rate, density, and temperature, it provides the precise stoichiometry needed for reactions. This minimizes waste, ensures consistent product yield quality, and is crucial for catalytic dosing and batch quality control.

Guided wave radar (GWR) or non-contact radar level transmitters are recommended. Both are immune to vapor layers and density changes. GWR is highly accurate for measuring the interface between two immiscible liquids (e.g., acid and solvent), ensuring SIL-rated (Safety Integrity Level) performance.

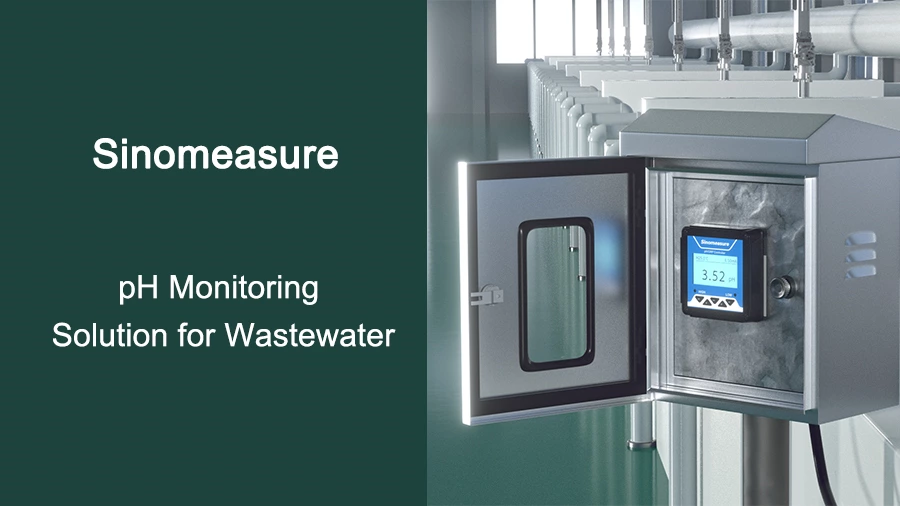

Differential pH electrodes housed in robust, retractable assemblies are used. The differential design minimizes ground loop errors, and the reference junction is designed for maximum lifespan in chemically aggressive and high-temperature environments, ensuring long-term calibration stability.

A flush diaphragm pressure transmitter is the safest choice. The diaphragm is mounted directly to the process connection, eliminating internal pockets where viscous or crystallizing media can accumulate, ensuring precise pressure readings and reducing maintenance costs.

The preferred method is using a Coriolis mass flow meter. It is a true mass meter, unaffected by the fluid's conductivity, and provides a high level of intrinsic safety due to its robust, all-metal construction and lack of moving parts.

A high-sensitivity trace gas analyzer is required. These instruments (such as those using Zirconia or Tunable Diode Laser Spectrometry) provide parts-per-million (ppm) or parts-per-billion (ppb) level detection, essential for maintaining the integrity of products sensitive to oxidation or hydrolysis.

A multipoint thermocouple assembly is used. This system consists of multiple thermocouples housed within a single protective thermowell, allowing operators to monitor the temperature gradient at various depths within the reactor simultaneously, critical for managing exothermic reaction control and safety.

Sinomeasure has been dedicated to industrial process automation for decades, focusing on the research, development, and manufacturing of precision sensors and instruments. Our main products include water analysis instruments, recorders, pressure transmitters, flowmeters, and other field instruments used in a wide range of process industries.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.