Sinomeasure provides advanced measurement and monitoring solutions for energy storage, data centers, and industrial cooling systems. Our instruments ensure stable thermal management, efficient energy conversion, and reliable system performance.

From cooling water circulation to battery energy storage safety monitoring, Sinomeasure supports smart energy applications with high accuracy and reliability.

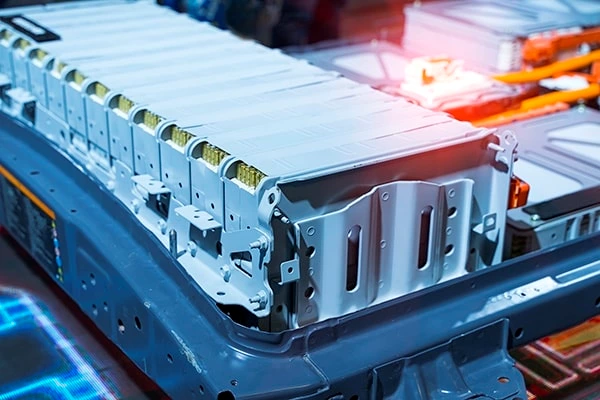

Industrial and commercial energy storage systems

Liquid cooling systems for battery packs and power equipment

HVAC and chiller water circulation control

Cooling tower and condenser monitoring

Data center temperature and humidity management

Battery Energy Storage Systems (BESS) require precise temperature control (thermal management) to maximize charge/discharge efficiency and prevent thermal runaway. Accurate flow meters (Ultrasonic or Magnetic) are essential to ensure the exact quantity of coolant (e.g., glycol mixture) is delivered to each battery rack, preventing localized overheating.

The Ultrasonic flow meter (Clamp-on) is ideal. It provides non-intrusive measurement with zero pressure drop, directly contributing to HVAC system energy efficiency by reducing pump power consumption. It is also excellent for temporary audits and monitoring without process shutdown.

RTD (PT1000) sensors installed with dual immersion thermowells (supply and return) are recommended. The PT1000 offers superior stability and accuracy over a narrow range, essential for calculating the precise ∆T (delta T) used in BMS energy calculations and for monitoring the thermal load.

Yes, by combining a flow meter (Ultrasonic or Magmeter) with two highly accurate ∆T Temperature Sensors (supply and return), systems can act as a thermal energy meter (BTU meter). This provides direct energy consumption and billing data in kW or BTU/hr.

A differential pressure (DP) transmitter is often used across filters, coils, and pumps. This measures the pressure drop, indicating filter clogging or pump efficiency, allowing for proactive maintenance before system performance degrades.

Glycol mixtures have different density, viscosity, and thermal properties than water. All flow meters and temperature sensors must be configured with a compensation table based on the glycol concentration. For Ultrasonic meters, the sound speed adjustment is critical.

A guided wave radar (GWR) or hydrostatic level sensor is typically used. GWR is advantageous because its measurement is less affected by the high vapor pressure and turbulence common in refrigerant storage vessels.

A high-stability humidity and temperature transmitter is required. These instruments use capacitive or polymer sensors to monitor relative humidity (RH) to prevent static discharge (too low RH) or condensation (too high RH), both of which can lead to critical electronic failure.

Sinomeasure has been dedicated to industrial process automation for decades, focusing on the research, development, and manufacturing of precision sensors and instruments. Our main products include water analysis instruments, recorders, pressure transmitters, flowmeters, and other field instruments used in a wide range of process industries.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.