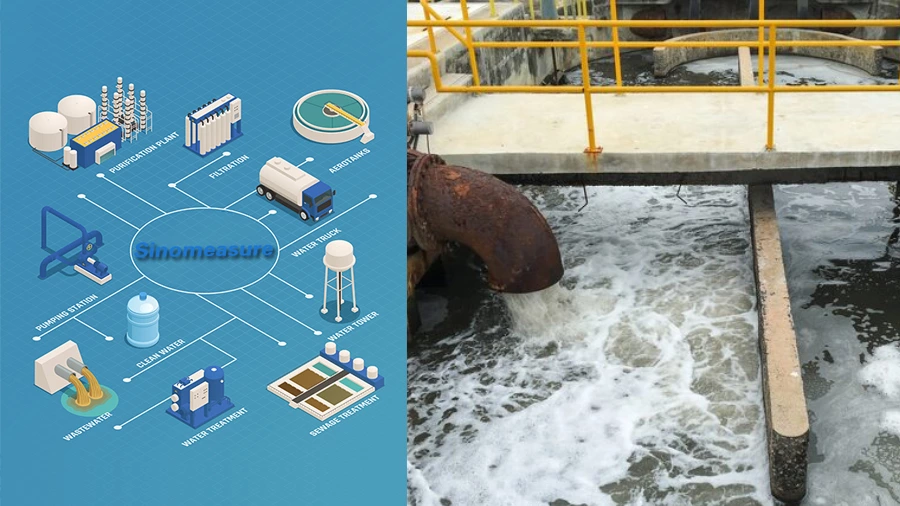

Sinomeasure provides advanced measurement and control solutions designed to ensure accuracy, reliability, and efficiency in water and wastewater applications.

From drinking water treatment to sewage monitoring, our instruments help operators achieve precise process control, reduce maintenance costs, and meet regulatory standards.

Water treatment plants and filtration systems

Wastewater collection and sewage networks

Industrial effluent monitoring and discharge control

Groundwater and surface water level monitoring

Sludge management and chemical dosing systems

Continuous online analysis, particularly for parameters like pH, ORP, DO, and Turbidity, ensures real-time data fidelity for environmental reporting. This minimizes the risk of non-compliance fines and prevents discharge violations by enabling immediate process adjustments. Our robust sensors are designed for sustained accuracy, reducing calibration frequency in demanding biological systems.

The electromagnetic flow meter (Magmeter) is the industry standard. Its non-intrusive design is immune to pressure loss and ideal for measuring conductive liquids with solids (sludge) or abrasive chemicals (dosing). For highly viscous or non-conductive water, a clamp-on ultrasonic flow meter provides non-contact reliability.

The radar level transmitters is highly recommended for precise measurement unaffected by foam, temperature changes, or vapor blankets. For sumps or basins with heavy sludge/debris, a hydrostatic level transmitter provides reliable, submersible performance, offering robust protection against highly corrosive media.

DO sensor drift is typically caused by sensor fouling or poisoning. Here, the optical DO sensors which require significantly less maintenance and frequent calibration compared to traditional electrochemical (amperometric) sensors, improving the stability of the aeration control system.

The disinfection stage requires accurate measurement of residual chlorine (Free or Total Cl₂). High-precision Amperometric Chlorine Analyzers with self-cleaning mechanisms are deployed to ensure reliable, drift-free measurement, which is essential for both public safety and chemical optimization.

The most effective method is using an open channel flow meter, which combines a primary device (like a Flume or Weir) to create a specific flow-to-level relationship, and an ultrasonic or radar level sensor to measure the height of the water, calculating the flow rate.

Retractable and Self-Cleaning Sensor Assemblies are recommended. These systems employ high-velocity jet sprays or mechanical wipers to periodically clean the sensor surface, preventing mineral scale buildup and maintaining electrode responsiveness and accuracy without process shutdown.

A differential pressure (DP Transmitter) is used to measure the pressure across the filter bed (inlet pressure minus outlet pressure). As the filter clogs, the DP increases. This measurement provides the most accurate and timely indication of when a backwash cycle is required, optimizing filtration time and water usage.

Sinomeasure has been dedicated to industrial process automation for decades, focusing on the research, development, and manufacturing of precision sensors and instruments. Our main products include water analysis instruments, recorders, pressure transmitters, flowmeters, and other field instruments used in a wide range of process industries.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.