What is HVAC?

HVAC stands for heating, ventilation, and air conditioning. It refers to the technology and systems used to control the indoor environment of buildings, including temperature, humidity, and air quality. HVAC systems are used in a wide range of settings, including residential homes, commercial buildings, and industrial facilities.

In heating mode, an HVAC system works by generating and distributing the warm air or water throughout a building to maintain a comfortable indoor temperature. In cooling mode, the system removes heat and moisture from the air and circulates cool air throughout the building. Ventilation refers to the process of exchanging indoor air with outdoor air to maintain air quality and prevent the buildup of harmful gases and pollutants.

HVAC systems can be very complex and may include a variety of components, such as heating and cooling equipment, ductwork, fans, filters, and controls. Proper installation, maintenance, and operation of HVAC systems are essential to ensure optimal performance and energy efficiency, as well as to maintain indoor air quality and comfort.

What is the role of flow meters in HVAC applications?

Flow meters play a crucial role in HVAC applications by measuring the flow rate of fluids, such as water or air, within the HVAC system. HVAC systems rely on the precise control of fluid flow to maintain proper temperature and humidity levels, as well as to ensure energy efficiency.

In heating mode, flow meters are used to measure the flow rate of hot water or steam that is circulated through the heating system to maintain the desired indoor temperature. In cooling mode, flow meters measure the flow rate of chilled water or refrigerant that is circulated through the cooling system to remove heat from the indoor environment.

Flow meters can also be used to monitor the flow rate of ventilation air, which is important for maintaining indoor air quality and preventing the buildup of harmful gases and pollutants. By accurately measuring flow rates, HVAC systems can optimize energy efficiency, reduce operating costs, and improve system performance.

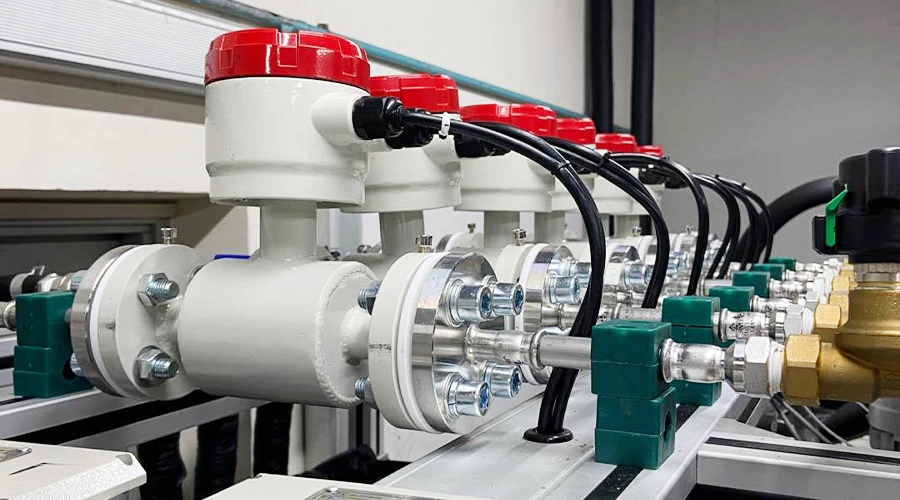

There are several types of flow meters used in HVAC applications, including differential pressure meters, magnetic meters, ultrasonic meters, and thermal meters. The choice of flow meter depends on factors such as the fluid being measured, the required accuracy and range, and the cost of the meter. Proper installation, calibration, and maintenance of flow meters are essential to ensure accurate and reliable performance.

How many types of flow meters used in the HVAC industry? And what are they?

There are several types of flow meters used in the HVAC industry, including:

Differential pressure meters: These meters measure the difference in pressure across an obstruction in the flow path, such as an orifice plate or Venturi. The pressure difference is proportional to the flow rate, and the meter is calibrated to provide accurate measurements over a specified range.

Magnetic flow meters: These meters use a magnetic field to measure the flow rate of conductive fluids, such as water or glycol. The magnetic field induces a voltage in the fluid as it passes through the meter, and the voltage is proportional to the flow rate. The meter is calibrated to provide accurate measurements over a specified range.

Ultrasonic flow meters: These meters use ultrasonic waves to measure the flow rate of fluids. They work by emitting ultrasonic pulses through the fluid and measuring the time it takes for the pulses to travel upstream and downstream. The difference in time is proportional to the flow rate, and the meter is calibrated to provide accurate measurements over a specified range.

Thermal flow meters: These meters use a thermal sensor to measure the flow rate of fluids. They work by heating a portion of the fluid and measuring the temperature difference between upstream and downstream points. The temperature difference is proportional to the flow rate, and the meter is calibrated to provide accurate measurements over a specified range.

Vortex shedding flow meters: These meters use the principle of vortex shedding to measure the flow rate of fluids. They work by placing a bluff body in the flow path, which creates vortices that are shed downstream. The frequency of vortex shedding is proportional to the flow rate, and the meter is calibrated to provide accurate measurements over a specified range.

The choice of flow meter depends on factors such as the fluid being measured, the required accuracy and range, and the cost of the meter. Proper installation, calibration, and maintenance of flow meters are essential to ensure accurate and reliable performance.

What is the flow rate of HVAC system?

The flow rate of an HVAC system can vary depending on the specific application and system design. In general, the flow rate is the volume of fluid, typically air or water, that passes through the system per unit of time and is measured in cubic feet per minute (CFM) or gallons per minute (GPM), respectively.

For example, in a heating system, the flow rate of hot water or steam is typically measured in GPM, while in a cooling system, the flow rate of chilled water or refrigerant is typically measured in GPM or CFM.

The flow rate is an important parameter in HVAC system design and operation, as it affects the temperature, humidity, and air quality of the indoor environment. The proper flow rate is critical to ensuring efficient and effective heating and cooling, as well as maintaining optimal indoor air quality.

Flow rate can be controlled through the use of valves, dampers, and variable frequency drives (VFDs), which adjust the speed of pumps and fans to maintain the desired flow rate. Proper measurement and monitoring of flow rate are essential to ensure optimal system performance, energy efficiency, and occupant comfort.

What is the maximum air flow for HVAC?

The maximum air flow for an HVAC system can vary depending on the specific application and system design. In general, the maximum air flow rate is determined by factors such as the size and capacity of the air handling unit (AHU), the size and number of supply and return ducts, and the size and capacity of the fans or blowers used in the system.

For example, a typical residential HVAC system might have a maximum air flow rate of 1,200 to 1,500 cubic feet per minute (CFM), while a larger commercial system might have a maximum air flow rate of 50,000 to 100,000 CFM or more.

It is important to note that the maximum air flow rate is not always desirable or necessary, as it can result in high energy consumption, noise, and other issues. HVAC systems should be designed and operated to achieve the desired indoor air quality and comfort levels while optimizing energy efficiency and minimizing operating costs.

Proper sizing, installation, and maintenance of the HVAC system components, such as ducts, filters, and fans, are critical to ensuring optimal air flow and system performance. Regular inspection and cleaning of the ducts and other components can help to maintain optimal air flow and indoor air quality.

What are the different types of flow in HVAC?

In HVAC systems, there are generally two types of flow: air flow and fluid flow.

Air flow:

Air flow refers to the movement of air through an HVAC system. In heating, ventilation, and air conditioning systems, air flow are used to distribute heated or cooled air to different parts of a building or space. The different types of air flow in HVAC systems include:

- Supply air flow: Supply air flow is the flow of air that is delivered to a space to maintain a desired temperature, humidity level, and air quality.

- Return air flow: Return air flow is the flow of air that is drawn back into the HVAC system from a space after it has been heated, cooled, or filtered.

- Exhaust air flow: Exhaust air flow is the flow of air that is removed from a space, typically through a dedicated exhaust duct, to remove odors, humidity, or contaminants.

Fluid flow:

Fluid flow refers to the movement of fluids, such as water, refrigerant, or glycol, through an HVAC system. Fluid flow is used to transfer heat energy between different parts of the system and to regulate temperature and humidity levels. The different types of fluid flow in HVAC systems include:

- Primary fluid flow: Primary fluid flow is the flow of fluid, typically water or refrigerant, that circulates through the primary heating or cooling equipment, such as boilers, chillers, or heat pumps.

- Secondary fluid flow: Secondary fluid flow is the flow of fluid that circulates through the distribution system, such as pipes or coils, to transfer heat energy to different parts of a building or space.

- Tertiary fluid flow: Tertiary fluid flow is the flow of fluid that is used for other purposes, such as maintaining water temperature in a hot water tank or circulating glycol to prevent freezing in a refrigeration system.

Proper measurement and control of air and fluid flow are critical to ensuring optimal system performance, energy efficiency, and occupant comfort in HVAC systems.

How is HVAC efficiency measured?

The efficiency of an HVAC (heating, ventilation, and air conditioning) system can be measured in several ways, depending on the specific parameters and performance indicators being evaluated. Here are some common methods used to measure HVAC efficiency:

Seasonal Energy Efficiency Ratio (SEER): SEER is a measure of the cooling efficiency of an air conditioning system over an entire season, calculated by dividing the total cooling output over a cooling season by the total electrical energy input during the same period. The higher the SEER rating, the more efficient the system is.

Annual Fuel Utilization Efficiency (AFUE): AFUE is a measure of the heating efficiency of a furnace or boiler, calculated by dividing the total heat output during a heating season by the total fuel input during the same period. The higher the AFUE rating, the more efficient the system is.

Energy Efficiency Ratio (EER): EER is a measure of the cooling efficiency of an air conditioning system under a specific set of conditions, calculated by dividing the cooling output by the electrical energy input at a specific outdoor and indoor temperature. The higher the EER rating, the more efficient the system is.

Coefficient of Performance (COP): COP is a measure of the heating efficiency of a heat pump, calculated by dividing the heating output by the electrical energy input. The higher the COP rating, the more efficient the system is.

Heating Season Performance Factor (HSPF): HSPF is a measure of the heating efficiency of a heat pump over an entire heating season, calculated by dividing the total heating output over a heating season by the total electrical energy input during the same period. The higher the HSPF rating, the more efficient the system is.

In addition to these metrics, other factors that can impact HVAC efficiency include proper sizing and installation of equipment, adequate insulation and air sealing, regular maintenance and cleaning, and use of programmable thermostats and other energy-saving strategies. Regular monitoring and evaluation of system performance can help to identify opportunities for improving efficiency and reducing energy costs in HVAC systems.

Español

Español Русский

Русский