What is Wastewater Treatment?

Wastewater treatment is the process of converting wastewater – water that is no longer needed or is no longer suitable for use – into clean water that can be discharged back into the environment. It’s formed by a number of activities including bathing, washing, using the toilet, and rainwater runoff. Wastewater is full of contaminants including bacteria, chemicals and other toxins. Its treatment aims at reducing the contaminants to acceptable levels to make the water safe for discharge back into the environment.

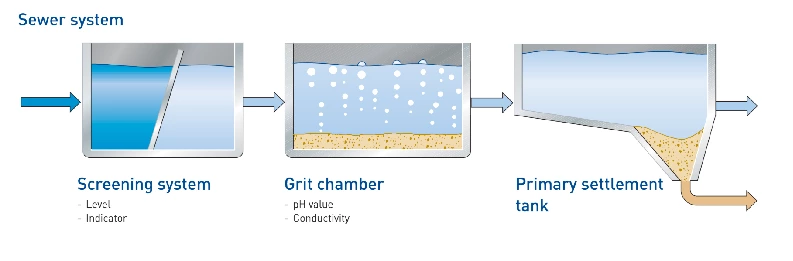

The Wastewater Treatment Process Steps by Steps

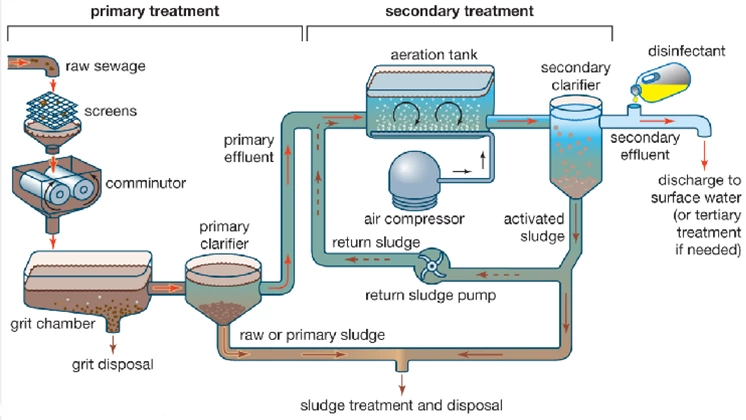

Primary Treatment

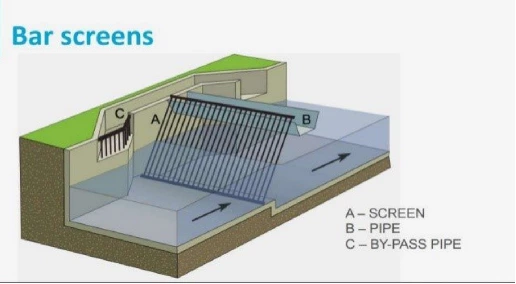

The primary treatment is the first stage in the process of treating wastewater in a wastewater treatment plant. It involves the physical removal of solids and some organic materials from the wastewater through a series of processes such as screening, grit removal, sedimentation, and flotation. During screening, large objects such as sticks, rags, and plastics are removed from the wastewater. The grit removal process eliminates sand, gravel, and other heavy inorganic materials that can damage equipment downstream. In sedimentation, the wastewater is allowed to sit in large tanks for several hours to allow the heavy solids to settle at the bottom, forming a layer of sludge. The sludge is then removed and sent for further treatment. Finally, flotation involves injecting air into the wastewater to encourage the formation of a floating scum layer, which is skimmed off the top.

Overall, primary treatment reduces the amount of suspended solids, organic matter, and other pollutants in the wastewater, making it easier and more efficient to treat in the subsequent treatment processes. Primary treatment is often followed by secondary and tertiary treatment processes to further remove impurities and achieve the desired level of water quality.

Secondary Treatment

Secondary treatment is the second stage of the wastewater treatment process that aims to further purify the wastewater after primary treatment. The main goal of secondary treatment is to remove the organic matter, suspended solids, and other contaminants that could not be removed during primary treatment.

Secondary treatment typically involves the use of biological processes to break down the remaining organic matter. The most common biological process used in secondary treatment is the activated sludge process, where microorganisms consume the organic matter and convert it into carbon dioxide, water, and more microorganisms.

Other secondary treatment methods include the trickling filter process, the rotating biological contractor process, and the oxidation ditch process.

Once secondary treatment is complete, the treated wastewater is disinfected to eliminate any remaining harmful pathogens, and then discharged into the environment. Secondary treatment is a critical step in the wastewater treatment process to ensure the protection of public health and the environment.

Types of Screen

- Coarse screens: 40-100mm

- Fines screens: 4-10mm

What is a grit chamber?

A grit chamber is a component of a wastewater treatment plant designed to remove heavy inorganic solids, such as sand, gravel, and rocks, from wastewater before they can cause damage to downstream process equipment. The grit chamber works by slowing down the flow of wastewater so that the heavy particles can settle to the bottom of the chamber, where they can be removed and disposed of properly. The grit chamber is usually located at the beginning of the treatment process, before the wastewater enters the primary treatment stage. By removing these heavy particles, the grit chamber helps to protect downstream process equipment, such as pumps, valves, and pipes, from abrasion and damage.

What is Sedimentation tank?

A sedimentation tank, also known as a clarifier, is a component in the wastewater treatment process that allows solids and liquids to separate from each other through gravity. The tank is a large rectangular or circular basin with a slow flow rate that allows heavy particles, such as sand, grit, and organic matter, to settle to the bottom of the tank while the lighter particles, such as fats, oils, and grease, float to the top to form a scum layer.

During the process, the wastewater flows into the sedimentation tank and is allowed to sit for several hours, allowing the particles to settle. The settled sludge is then removed from the bottom of the tank by a scraper mechanism and sent to a sludge processing unit, while the scum layer is removed from the top of the tank by a skimming mechanism and sent to the grease trap.

Sedimentation tanks are a crucial part of the wastewater treatment process as they help to reduce the amount of suspended solids and organic matter in the water before it is sent for further treatment. The efficiency of the sedimentation tank is dependent on factors such as flow rate, detention time, and sludge removal mechanism.

What's the difference between Grit chamber and Sedimentation tank?

Both grit chambers and sedimentation tanks are components of wastewater treatment plants, but they serve different purposes.

A grit chamber is designed to remove heavy, coarse materials such as sand, gravel, and other grit from wastewater. It typically operates as a primary treatment process and is located near the beginning of the treatment plant. The grit chamber slows down the flow of wastewater, allowing the heavier materials to settle to the bottom where they are removed by mechanical means. The purpose of the grit chamber is to protect downstream equipment from damage caused by abrasive materials, as well as to prevent clogging of pipes and other equipment.

A sedimentation tank, on the other hand, is designed to remove suspended solids and organic matter from wastewater. It is typically used as a secondary treatment process and is located after the grit chamber. The sedimentation tank operates by slowing down the flow of wastewater and allowing the suspended particles to settle to the bottom, forming a layer of sludge. The clarified water is then skimmed from the top of the tank and further treated before discharge.

In summary, while both grit chambers and sedimentation tanks involve the settling of materials in wastewater, a grit chamber is designed specifically for heavy, coarse materials, while a sedimentation tank is designed to remove suspended solids and organic matter.

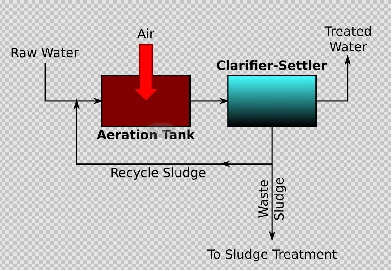

What is Activated sludge?

Activated sludge is a biological process used in wastewater treatment to treat organic matter and remove pollutants from wastewater. It involves mixing wastewater with microorganisms in a treatment tank or basin, where they break down and consume organic material. The microorganisms form a mass of flocculated or clumped solids called "activated sludge," which can then be separated from the treated wastewater using a sedimentation tank.

The activated sludge process relies on aeration to provide oxygen for the microorganisms to consume the organic material. The amount of oxygen, along with the mixing and retention time, are key factors in optimizing the process. The end result is treated wastewater that can be safely discharged into the environment or reused.

Activated sludge is one of the most widely used wastewater treatment methods and is known for its effectiveness in removing organic material and nutrients, including nitrogen and phosphorus. It is commonly used in municipal wastewater treatment plants, as well as in industries such as food processing, chemical manufacturing, and paper production.

What is Activated sludge Process?

The activated sludge process is a biological treatment process used to treat wastewater. It involves introducing a mixed culture of microorganisms, referred to as activated sludge, to the wastewater to break down organic matter and remove pollutants.

In the activated sludge process, wastewater is first screened to remove large objects and then passed into an aeration tank where air is continuously pumped into the tank to provide oxygen for the microorganisms. The activated sludge culture is added to the aeration tank and mixed with the wastewater. The microorganisms in the activated sludge consume the organic matter in the wastewater, using it as a food source and breaking it down into simpler compounds.

After a period of aeration, the mixture of wastewater and activated sludge flows into a sedimentation tank. The activated sludge settles to the bottom of the tank, forming a sludge layer, while the treated wastewater flows over a weir and out of the tank. The settled activated sludge is then recirculated back to the aeration tank to continue the treatment process.

The activated sludge process is an effective way to treat wastewater and remove organic matter, nitrogen, and phosphorus from the wastewater. It is widely used in municipal and industrial wastewater treatment plants around the world.

Instruments used in Wastewater Treatment Process

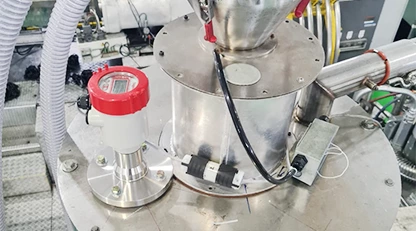

| Wastewater Treatment Process | The Main Parameters | Instruments |

| Regulating tank | Regulating tank liquid level, influent pH value (6~9), influent SS (<400mg/L), influent flow | Ultrasonic/submersible liquid level meter, online pH meter, online SS meter, electromagnetic flow meter |

| Anaerobic tank | Anaerobic tank liquid level, dissolved oxygen (<0.2mg/L) | Ultrasonic/submersible liquid level gauge, online DO instrument |

| Aerobic pool | Aerobic pool liquid level, dissolved oxygen (2~3mg/L), pH value, MLSS value | Ultrasonic/submerged liquid level gauge, online DO meter, online pH meter, sludge concentration meter |

| MBR membrane tank | MBR membrane tank MBR liquid level, dissolved oxygen (2~3mg/L), MLSS value, membrane tank landscape pressure, pH value | Ultrasonic/submersible liquid level gauge, online DO meter, sludge concentration meter, pressure transmitter, online PH meter |

| Equipment room | Air duct/pump pressure, dosing flow | Pressure transmitter, electromagnetic flow meter |

| Effluent | Effluent pH value (6~9), effluent SS (<30mg/L), effluent turbidity, effluent flow | Online pH meter, online SS meter, Online turbidity meter, Electromagnetic flow meter |

Español

Español Русский

Русский