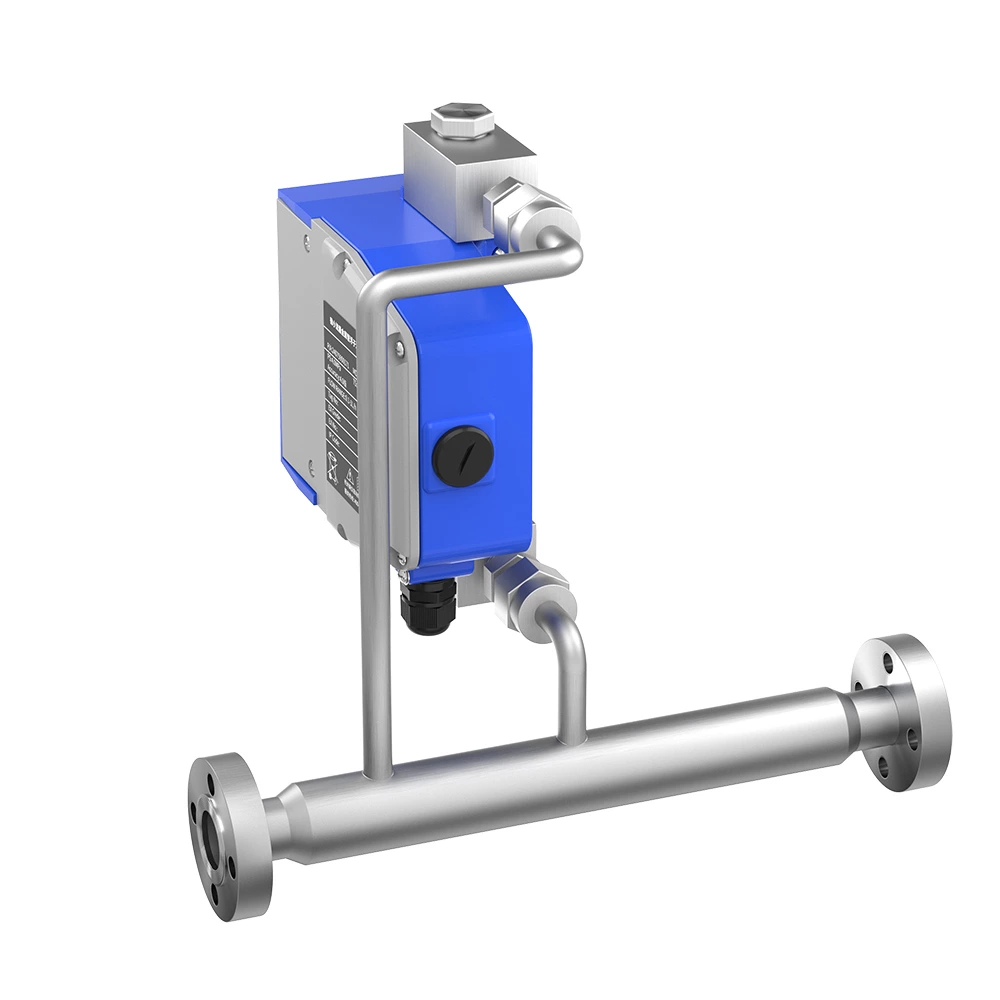

FRM200 micro metal tube float flowmeter

All-Metal Construction for High Durability and Resistance to High Temperatures, High Pressures, and Corrosive Media

Precision Adjustment Needle Valve for Accurate Setting and Control of Extremely Low Flow Rates

Buoyancy-Based Measurement Principle Ensures Reliable and Stable Flow Rate Detection

Magnetic Coupling System for Non-Contact Transmission of Float Movement, Enhancing Accuracy and Longevity

Alarm Module with Upper and Lower Limit Alerts for Enhanced Monitoring and Operational Safety

Wide Application Range Including Gas Chromatography, Pharmaceutical Machinery, Nuclear Power, Marine Equipment, and Laboratory Apparatus

| Specification | Detail |

|---|---|

| Series Number | FRM200 (Micro metal tube float flowmeter) |

| Measurement Medium | Liquid (1-150L/h) | Gas (16-4800L/h) |

| Process Connection | NPT1/4 inner thread | HG/T20592 PN40 DN15 flange connection | ISO2852 50.5 card sleeve | Card sleeves (6mm, 8mm, 10mm, 12mm) |

| Meter Tube & Float Material | 316LSS (Other options available) |

| Meter Tube Structure | Bottom inlet/top outlet | Right inlet/left outlet | Left inlet/right outlet | Side inlet/side outlet |

| Accuracy | 2.5 grade (Other options available) |

| Indicator Type | Aluminum alloy square housing with pointer or LCD display |

| Output & Power Supply | Options include two-wire system 4-20mA, HART, RS485, and more |

| Alarm | SPDT dry contact, NAMUR switch for upper/lower limit alarms |

| Flow Control Valve | Inlet or outlet needle valve options available |

| Constant Flow Valve Type | Low-pressure and high-pressure inlet/outlet pressure variation types |

| Electrical Interface & Protection Class | M16×1.5 cable gland, IP67 protection |

FRM200 Micro Metal Tube Float Flow Meter

The FRM200 Micro Metal Tube Float Flow Meter is specifically designed for measuring extremely small flows of gases and liquids. Featuring an all-metal structure, it is well-suited for applications requiring resistance to high temperatures, high pressures, and corrosive media. This meter finds extensive use in gas chromatography analysis, sampling equipment, laboratory apparatus, pharmaceutical machinery, nitrogen and argon supply systems, oxygenation devices, nuclear power, marine equipment, leak detection devices, and more.

Key Features:

- All-Metal Construction: Designed for resistance against high temperature, high pressure, and corrosive media.

- Precision Adjustment: Includes a flow adjustment needle valve for accurate setting and control of specific flow rates.

- Buoyancy-Based Measurement: Utilizes the principle of buoyancy for reliable and stable measurement of very low flow rates.

- Magnetic Coupling System: Ensures precise transmission of float movement to the indicator without physical contact.

- Alarm Module: Provides upper and lower limit flow alarms for enhanced monitoring and safety.

Applications include:

- Gas Chromatography Analysis: Precise flow control for analytical instruments.

- Sampling Equipment: Accurate measurement for environmental and industrial sampling.

- Laboratory Apparatus: Reliable flow measurement in research settings.

- Pharmaceutical Machinery: Critical for processes requiring controlled gas and liquid flow.

- Nuclear Power and Marine Equipment: Suitable for demanding environments where reliability is key.

*Available with various process connections, materials, and configurations to suit different application requirements.

Español

Español Русский

Русский