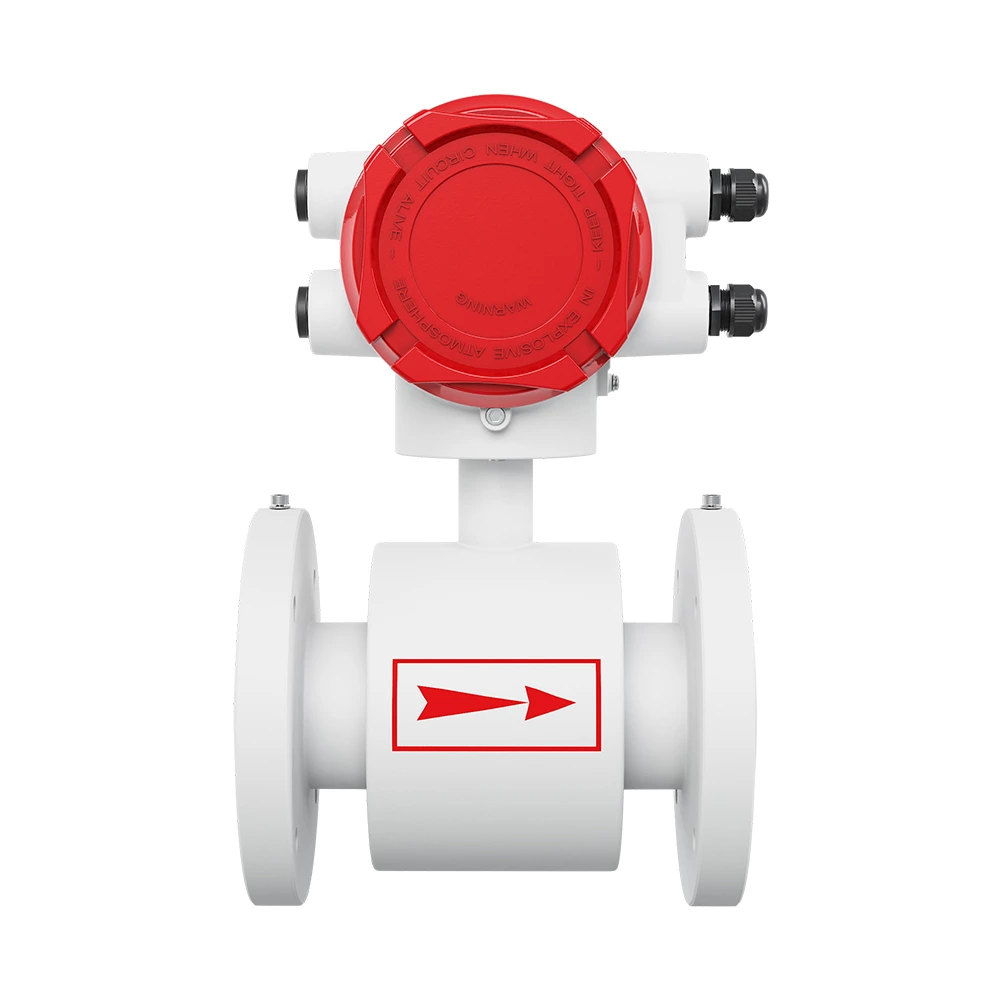

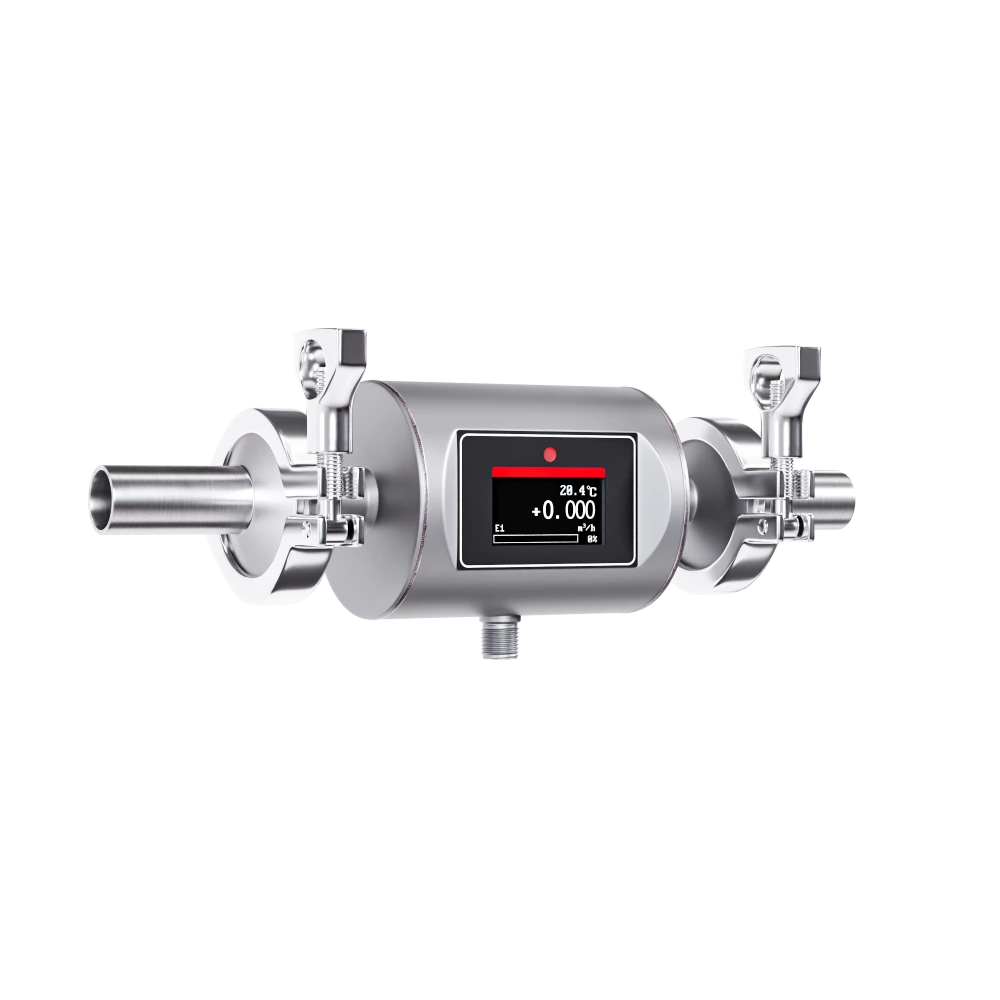

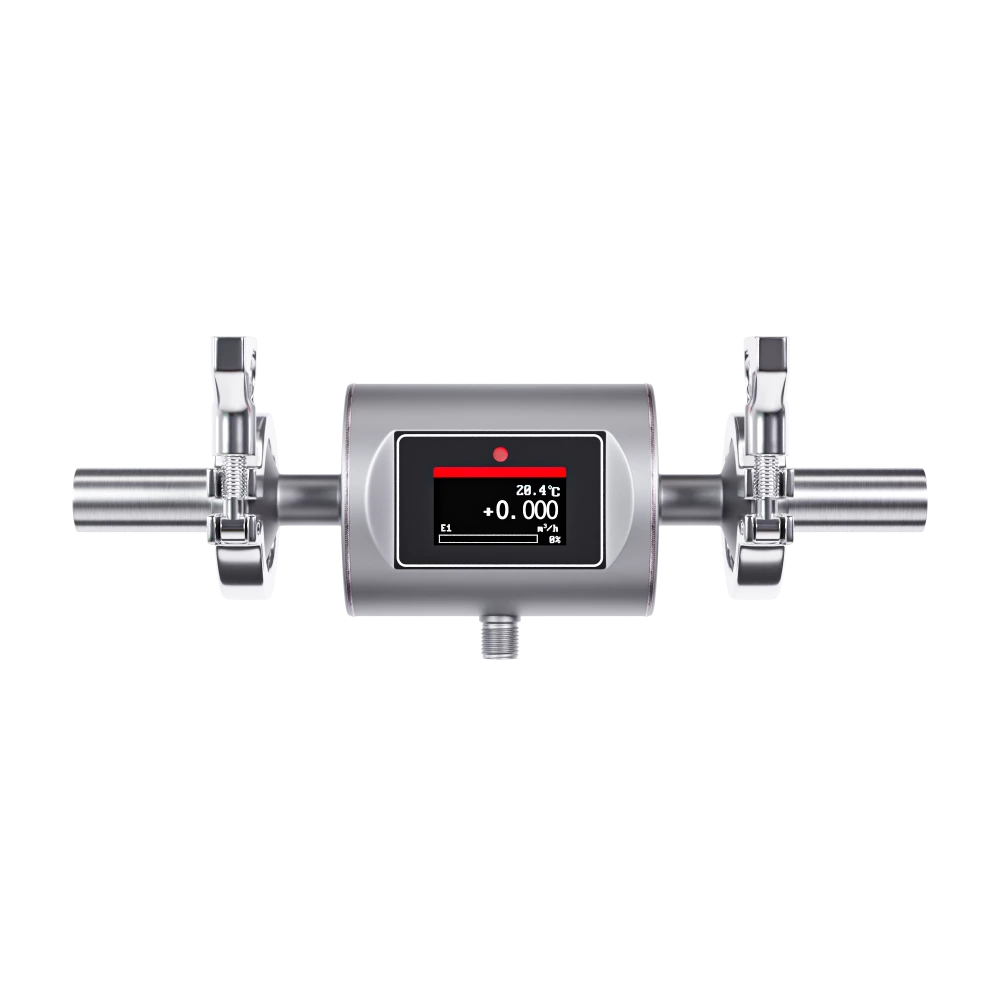

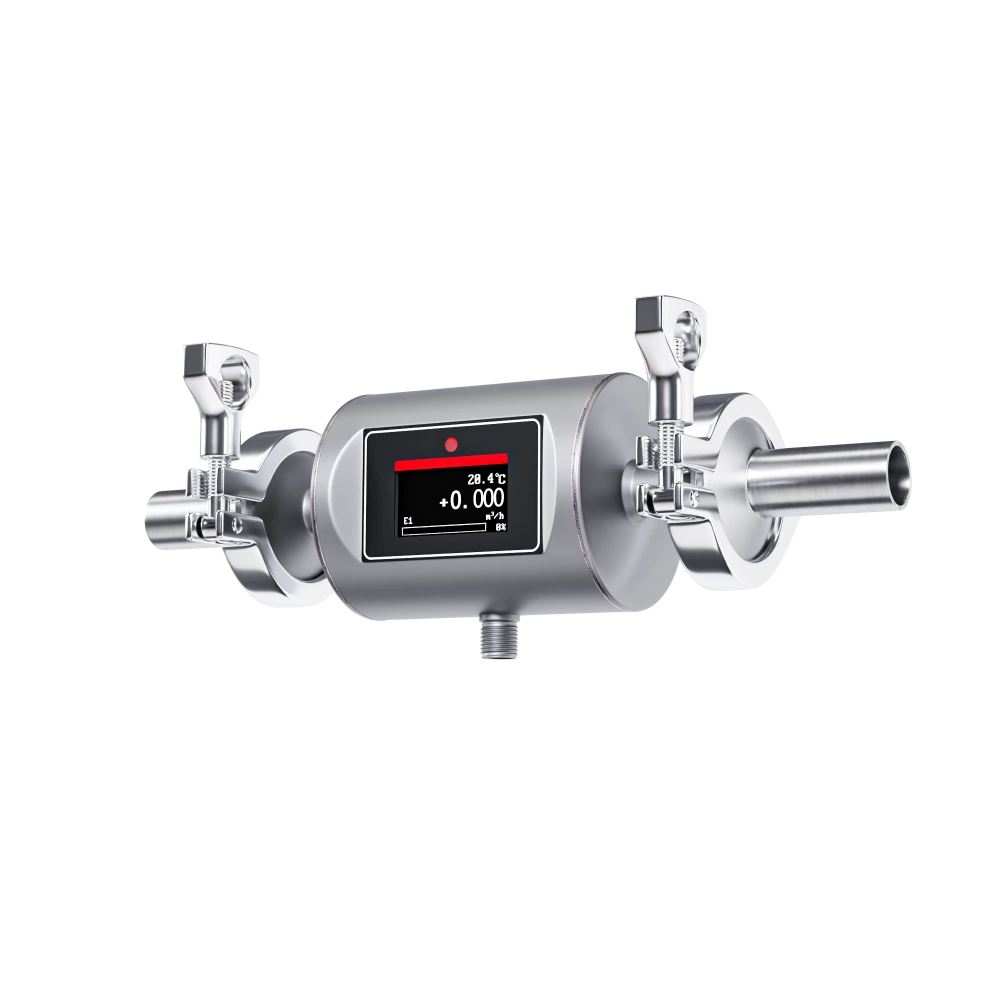

FCC800 Coriolis Mass Flowmeter: Accurate Liquid & Gas Measuring for Industrial/Pharmaceutical Usage

This FCC800 Coriolis flow meter is a precise measurement of mass flow, density, and temperature for marine fuel management, ballast systems, and industrial fluids. With remarkable features like robust, accurate, and easy to integrate for reliable performance at sea, this FCC800 Coriolis mass flow meter has been widely deployed in various applications.

- Direct and Multifunctional Measurement: Measures mass flow, density, temperature, and volumetric flow for reliable results with liquids, gases, slurries, or suspensions

- High Precision and Repeatability: Flow accuracy up to Level 0.15 (options: 0.2/0.5), density ±0.001 g/cm³, temperature ±1°C

- Robust Marine-Grade Durability: Withstands vibrations, shocks, and harsh marine conditions with IP67 protection, -40°C to 55°C range, and 95% humidity tolerance.

- Wide Compatibility and Range: Supports DN1 to DN150 diameters in various designs

- Seamless Integration and Outputs: Includes 4-20 mA analog, RS-485 Modbus, HART, and a user-friendly display for easy PLC/DCS/automation connections.

- Efficient Power and Installation: Uses ≤10W on 24VDC/220VAC, with compact design and up to PN63 pressure ratings, simplifying installs in tight spaces.

- Broad Application Suitability: Ideal for marine fuel management, ballast monitoring, chemical processing, food production, energy systems, wastewater treatment, and automation

Introduction

The FCC800 Coriolis Mass Flow Meter stands out by directly gauging the mass flow of fluids, whether liquids or gases, through the detection of subtle forces created when the substance moves through specially shaped, oscillating pipes.

Beyond just mass flow, this device also delivers readings on the fluid's density, its temperature, and even calculates volume based on the mass info. What makes it shine are traits like spot-on linearity, quick reaction times, and solid resistance to shakes and jolts, which suit it perfectly for setups in ships and offshore operations.

Built with marine standards and ISO guidelines in mind, the FCC800 leverages Coriolis tech to boost control over processes, sharpen fuel tracking, and heighten safety in nautical environments.

Working principle

At the heart of the FCC800 is the Coriolis effect, a smart way to measure flow using three main steps in its flow measurement:

- Starting the Vibration: The meter's tubes receive a steady buzz from mechanical drivers, creating a reliable rhythm that serves as the starting point for identifying any shifts caused by the flowing material.

- Flow and the Twist Effect: When the fluid passes through these humming tubes, it triggers Coriolis forces that slightly warp the tubes' movement: the bigger the flow's mass, the more noticeable the twist becomes.

- Picking Up and Crunching the Data: Sensors catch these tiny changes in the tubes, and the built-in processor turns them into precise calculations for mass flow, density, and temp. From there, the results feed out via analog signals, digital links, or bus systems to connect with broader controls.

Key features

Crafted for top-notch precision, toughness, and easy hookup to existing setups, the FCC800 Coriolis Mass Flow Meter for marine use holds up strong in tough, real-world conditions.

- Straightforward Mass Flow Reading: It captures mass flow head-on with Coriolis methods, skipping any tweaks for pressure or heat. This leads to consistent, trustworthy outcomes no matter if you're dealing with gases or liquids.

- Built-In Density and Temp Monitoring: All in one unit, it gives you mass flow alongside density and fluid temperature. Perfect for getting a live view of things like fuel handling or shipboard fluid ops.

- Tough Build for Sea Conditions: Its sturdy sensors are made to handle bumps, vibrations, and the rough ride of boats or rigs at sea. Ideal for non-stop use in challenging spots.

- Spot-On Precision and Reliability: With great straight-line accuracy and speedy feedback, it's spot-on for keeping tabs on fuels, ballast, or industrial mixes. It shrugs off outside noise for steady results even on the waves.

- Versatile Outputs and Connections: Offers 4-20 mA signals, pulse counts, and RS-485 for digital chats via Modbus. Slides right into ship controls, distributed systems, or automation networks.

- Broad Fluid Compatibility: Works with all sorts of densities and stickiness levels, from heavy oils and diesels to lubes, hydraulics, or even air. Its small size makes fitting it into tight ship spots a breeze.

- Easy Setup and Use: Comes with a clear screen and simple tweaks, speeding up installs and fixes. Helps cut time lost during setup or tweaks.

Specification

| Measured variables | Mass flow rate, density, temperature |

| Measuring medium | Gases, liquids, slurries, suspensions, etc |

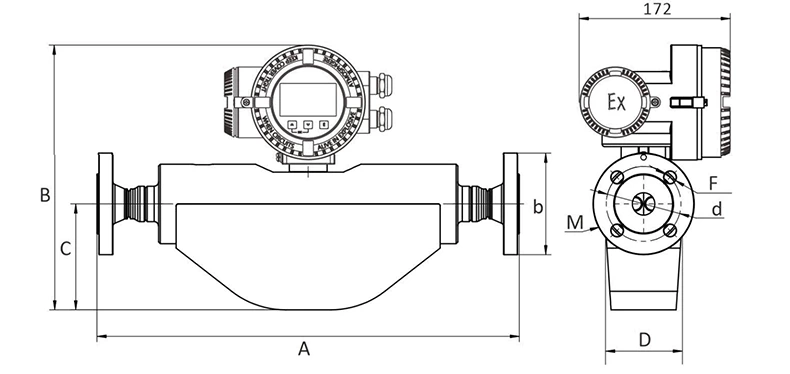

| Nominal diameter | U-shaped type: DN3~DN150 Micro-bend type: DN8~DN100 Straight pipe type: DN8~DN50 Inverted triangle type: DN1~DN2 |

| Range ratio | U-shaped type: 10:1 Micro-bend type: 10:1 Straight pipe type: 5:1 Inverted triangle type: 10:1 |

| Temperature measurement range | (-240~350)℃ |

| Accuracy | Flow volume: Level 0.15, Level 0.2, Level 0.5 Density: ±0.001g /cm³ ( ± 1kg / m³ ) Temperature: ± 1 ℃ or ± 0.5% × test value, whichever is greater. |

| Repeatability | 1/2 of the accuracy |

| Transmitter output | (4~20) mA, load resistance ≤ 750Ω |

| Communication | RS485 , MODBUS-RTU;Hart |

| Pulse output | Duty cycle: 10%~90% Pulse frequency: Maximum 10000Hz Active: Output current 10mA, open circuit voltage 30V |

| Power supply | 24VDC/220VAC |

| Power consumption | ≤ 10W |

| Nominal pressure | Clamp connection type: Pressure resistant PN16 Flange connection type: pressure resistant PN16, PN40, or PN63 |

| Ambient temperature | ( -40~55 ) ℃ (with display: -25 ℃~ 55 ℃) |

| humidity | ≤95% |

| Protection level | IP67 |

Applications

Tailored for exact tracking of mass flow, density, and heat in fluids, the FCC800 Coriolis Mass Flow Meter shines across various sectors, especially in marine and heavy-duty uses.

- Shipboard Fuel and Liquid Handling: Keeps a close eye on flows of ship fuels, oils, hydraulics, and support fluids, aiding in better tracking, smoother runs, and steady performance at sea.

- Balancing Water Ops: Tracks the movement of ballast water to keep ships stable and safe while loading or offloading cargo.

- Chem and Drug Making: Handles exact measurements for adding chemicals, managing reactions, and meeting strict production rules.

- Food and Drink Lines: Delivers precise amounts of liquids for mixing, ensuring batches turn out just right every time.

- Energy and Power Setups: Monitors water feeds, fuels, and coolants in plants or heating networks to fine-tune efficiency and keep things balanced.

- Water Treatment Facilities: Helps oversee flows in processing, cleaning, and outflow stages for reliable, rule-following operations.

- General Factory Automation: Supplies instant mass flow details for dosing, batching, and automated liquid management in manufacturing.

Español

Español Русский

Русский