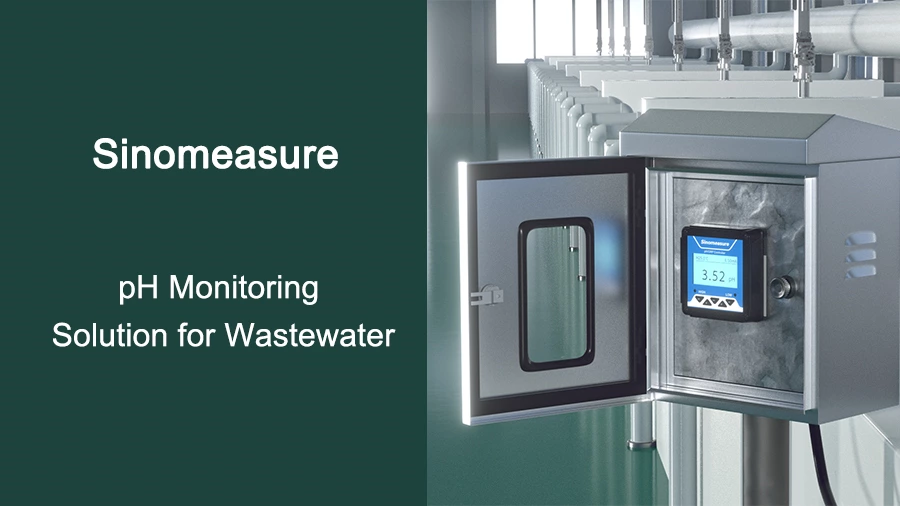

Efficient Wastewater Treatment for Printing Industry

Sinomeasure pH controllers and conductivity meters applied to optimize ink wastewater treatment

Client Background

With the national emphasis on environmental protection, the printing industry has shifted from extensive development to a new era of energy saving and emission reduction. Most printing companies now recognize the importance of implementing green printing practices. During printing operations, cleaning equipment generates wastewater with complex chemical composition, high COD, high color, and low biodegradability, which can severely pollute rivers and the environment if discharged untreated.

Project Overview

Shanghai Zhenchen Electromechanical Technology Co., Ltd. applied the reverse osmosis (RO) method to treat ink wastewater at a printing company. Compared to traditional methods, RO treatment provides higher efficiency, better effluent quality, compact equipment footprint, easier automation, and simplified management. It is particularly effective for high-concentration organic wastewater and hard-to-degrade industrial effluents.

Equipment Configuration

Key Benefits

- High efficiency in treating high COD and color wastewater.

- Compact design, easy to automate and manage.

- Improved effluent quality compared to conventional methods.

- Reliable monitoring using pH controllers and conductivity meters for accurate control.

Summary

The implementation of Sinomeasure pH controllers and conductivity meters ensures precise and scientific monitoring of printing wastewater treatment. This solution supports high-quality effluent discharge and contributes to environmental protection, aligning with China’s green manufacturing initiatives.

Project Snapshot

- Client: Printing Industry Company

- Industry: Printing & Packaging

- Application: Ink wastewater treatment monitoring

- Instruments: Sinomeasure pH Controllers, Conductivity Meters