Flow Measurement Solution for Textile Dyeing Process

Sinomeasure flow meters applied to monitor and optimize dye vat water usage at Lijia Textile

Client Background

Shantou Lijia Textile Industrial Co., Ltd., founded in 2006, specializes in textile weaving and dyeing. The company possesses professional technical staff dedicated to weaving and dyeing, along with advanced production management and quality inspection systems.

Project Overview

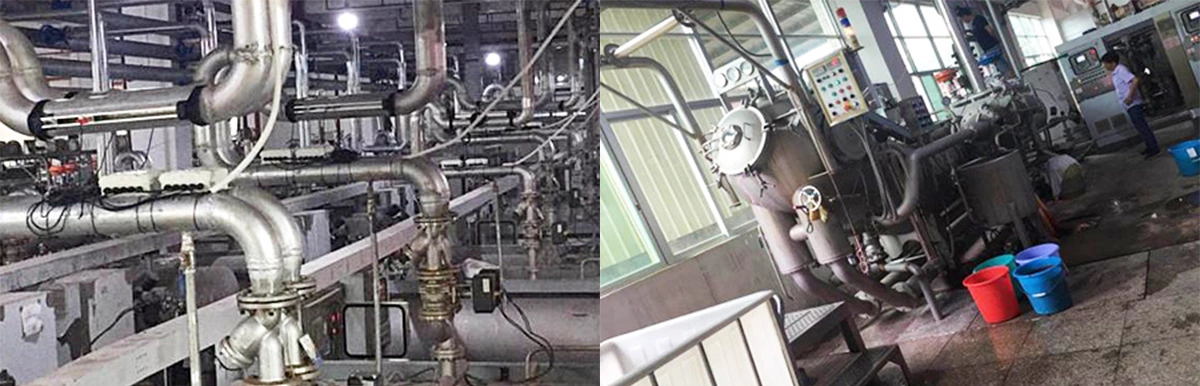

Lijia Textile utilized Sinomeasure flow meters to accurately measure the water input in dye vats. In total, more than 40 dye vats were equipped with Sinomeasure flow meters to monitor water usage and improve process control, optimizing operational costs.

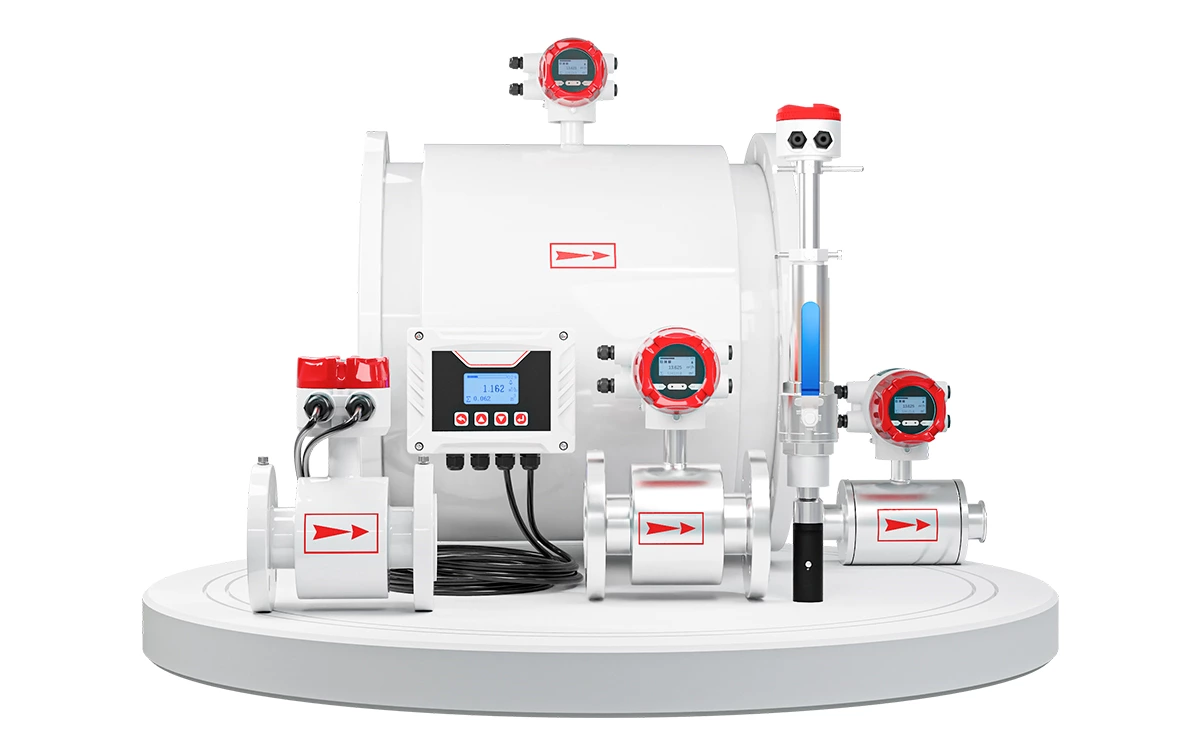

Equipment Configuration

- Sinomeasure Flow Meters

Key Benefits

- Precise measurement of cold and hot water injected into each dye vat for accurate process control.

- Supports water bath ratio and recycled water rate optimization, critical indicators for energy efficiency in textile dyeing.

- Helps optimize dyeing process and reduce operational costs by accurately controlling water consumption.

- Applied to over 40 dye vats, demonstrating scalability and reliability of the solution.

Summary

The implementation of Sinomeasure flow meters enables Lijia Textile to precisely control water usage in each dye vat, improve energy efficiency, and optimize production costs. The solution ensures accurate process monitoring and contributes to sustainable and cost-effective textile dyeing operations.

Project Snapshot

- Client: Shantou Lijia Textile Industrial Co., Ltd.

- Industry: Textile & Dyeing

- Application: Dye vat water flow monitoring

- Instruments: Sinomeasure Flow Meters