Domestic Wastewater Treatment — Instrumentation Solutions

Case: Application of Electromagnetic Flow Meter, Ultrasonic Level Meter & Online pH Meter

Project Overview

As urbanization advances and domestic wastewater discharge increases, advanced instrumentation and automation become essential for wastewater treatment plants. In this project, Sinomeasure provided a complete set of instrumentation — electromagnetic flow meters, ultrasonic level meters, and online pH meters — to support a full-scale domestic wastewater treatment process covering primary, secondary and tertiary treatment stages.

Key Facts

- Industry: Domestic Wastewater Treatment

- Instruments: Electromagnetic Flow Meter, Ultrasonic Level Transmitter, Online pH Transmitter

- Application Points: Inlet flow measurement, lift-station liquid level, biological tank pH monitoring

Why These Instruments?

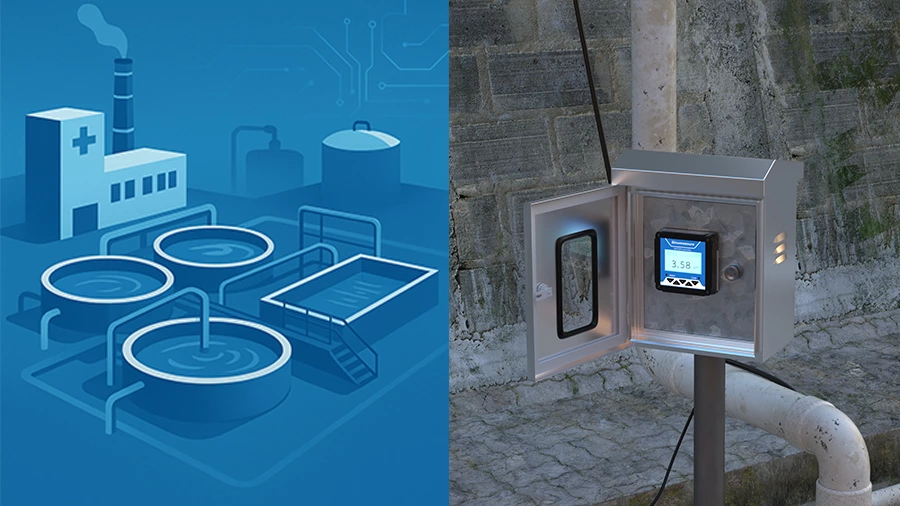

- Electromagnetic Flow Meter — Stable volumetric measurement even for sewage and complex media, suitable for flow measurement and billing or process control.

- Ultrasonic Level Transmitter — Ideal for lift-stations, grit chambers, sedimentation tanks; supports pump control and overflow prevention.

- Online pH Transmitter — Facilitates real-time pH monitoring before/after biological treatment and during dosing or disinfection steps, ensuring treatment efficiency.

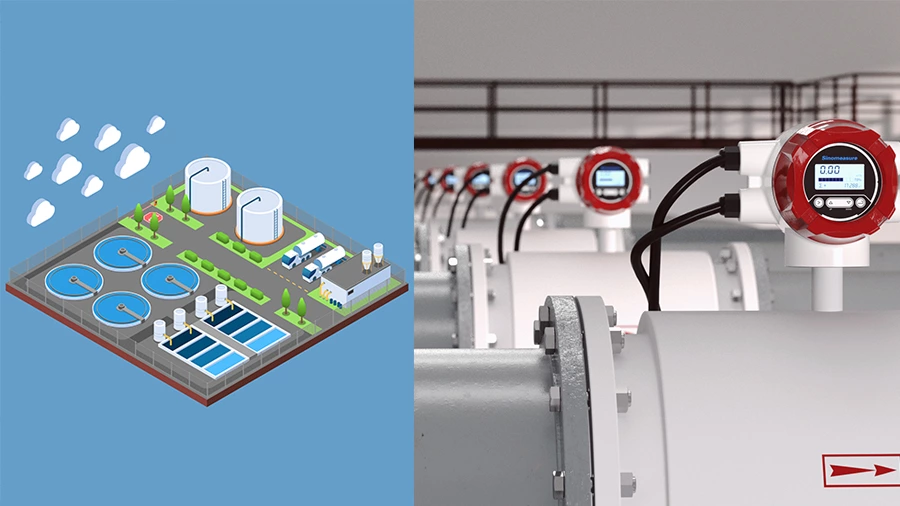

Wastewater Treatment Process Flow

The treatment process described in this case includes three main stages: primary (physical), secondary (biological) and tertiary (advanced) treatment, plus sludge handling. The following is a structured overview based strictly on the original data.

Primary Treatment (Physical)

Consists of screening, lift-pump, grit removal, and primary sedimentation. The primary treatment removes approximately 30% of BOD through physical separation.

Secondary Treatment (Biological)

Utilizes processes such as activated sludge (aeration tanks, oxidation ditches) or biofilm methods to degrade colloidal and dissolved organic pollutants (BOD, COD). Treatment efficiency reaches over 90% of organic load.

Tertiary Treatment (Polishing / Nutrient Removal)

Further treatment targets nutrients (e.g. nitrogen, phosphorus), recalcitrant organics, and other pollutants by using coagulation, filtration, adsorption or advanced biological/chemical methods.

Sludge Handling

Returned sludge maintains biological activity; excess sludge undergoes thickening, digestion and dewatering for final treatment or disposal.

Typical Process Flow Diagram (simplified)

Raw sewage → Coarse screen → Lift pump → Fine screen / Filtration → Grit chamber → Primary sedimentation

Primary effluent → Biological treatment → Secondary sedimentation

Secondary effluent → Disinfection or tertiary treatment → Discharge

Sludge → Thickening → Digestion → Dewatering → Disposal

Note: The above is a general workflow based on the referenced case. Actual plant design may vary depending on scale, influent characteristics and discharge standards.

Instruments Provided

For this wastewater treatment plant, the following instruments were supplied and recommended:

- Electromagnetic Flow Meter — for inlet and process flow measurement and billing / monitoring;

- Ultrasonic Level Transmitter — for lift station, equalization tank and clarifier level control;

- Online pH Transmitter — for biological tanks, dosing control and disinfection process monitoring.

Contact Us for Professional Solutions

Sinomeasure offers full-service instrumentation selection, system integration and after-sales support for wastewater treatment plants. Contact us to get an engineered solution, quotation or on-site support.

Get in Touch