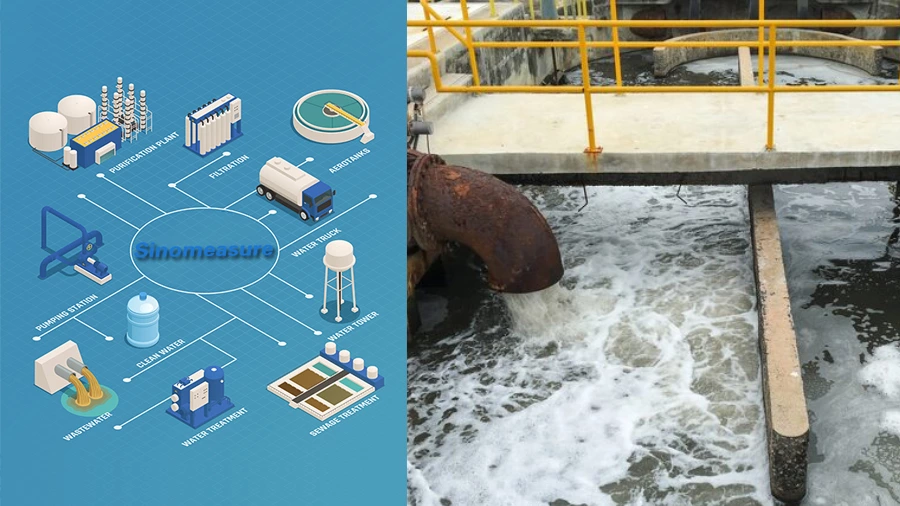

Wastewater Treatment – Oxidation Ditch Application

The oxidation ditch — also known as a continuous‑loop reactor — is a mature activated sludge wastewater treatment process. Developed in the 1950s by a Dutch public‑health institute, this process (originally designed by Dr. Pasveer) features a closed‑channel loop system: wastewater circulates through a long ditch (often of elliptical, circular or horseshoe shape), receiving aeration and biological treatment over an extended hydraulic retention time. As a variation of the activated sludge and extended‑aeration processes, the oxidation ditch combines advantages of simplicity, stable sludge settlement, and effective removal of both suspended and dissolved organics.

Project Overview

- Application Scenario: Oxidation Ditch (Continuous‑loop Activated Sludge Process)

- Instruments Installed: Online pH transmitter, Online dissolved oxygen (DO) transmitter, Online turbidity transmitter

- Purpose: Real‑time monitoring and control of pH, dissolved oxygen and turbidity to ensure stable biological treatment and effluent quality

Why Oxidation Ditch + Real‑time Monitoring Works?

Advantages of the Oxidation Ditch process:

- The long hydraulic retention time and sludge retention in the ditch allow both suspended and soluble organics to be degraded thoroughly.

- The process design is simple with minimal structures, enabling either a single combined clarification or no primary clarifier at all; this simplifies operation and maintenance.

- Due to extended sludge age, discharged sludge tends to be stable, requiring only thickening and dewatering — sludge digestion tanks may be omitted.

Challenges / Limitations:

- Oxidation ditches typically require larger land area compared with conventional activated‑sludge basins, due to the geometry and hydraulic layout.

- Mechanical aeration consumes more energy, leading to higher operational costs.

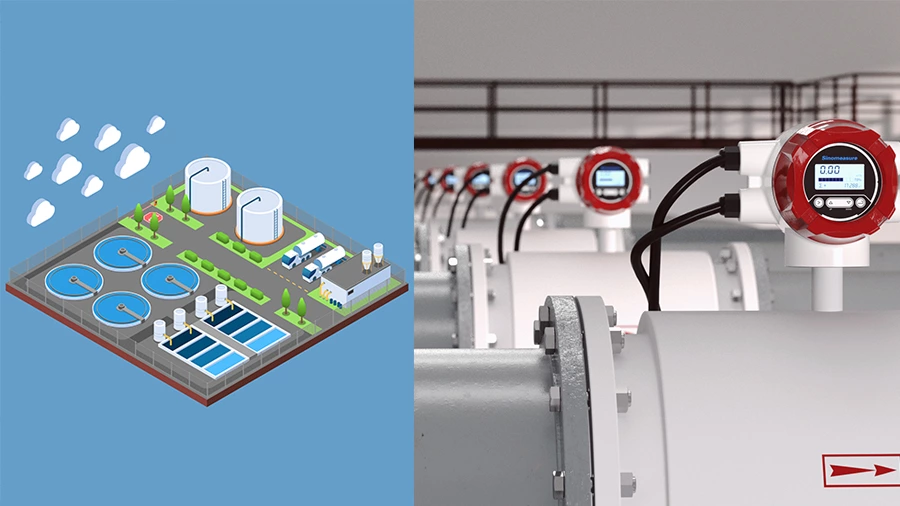

How Sinomeasure’s Instruments Help:

By installing online pH, DO and turbidity instruments, operators gain continuous, real‑time insight into critical biological treatment parameters. This enables:

- Rapid detection of process deviations (e.g. pH swings, oxygen depletion, turbidity fluctuations)

- Timely adjustment of aeration and sludge control to maintain optimal biological activity and effluent stability

- Assurance of effluent quality and compliance with discharge standards

- Reduction of manual sampling workload, and improved automation and process traceability.

Recommended Instrumentation Suite

For oxidation‑ditch and similar activated‑sludge systems, we recommend combining the following instruments for comprehensive monitoring and control:

- Online pH transmitter & pH sensor — for stable control of biological process pH values

- Online Dissolved Oxygen transmitter & sensor — for monitoring oxygen levels to support aerobic/ anoxic zones

- Online turbidity / SS / suspended solids sensor — for tracking sludge concentration / effluent clarity

These instruments, when used together, form an integrated monitoring platform that enables stable, efficient, and compliant wastewater treatment.

Why Choose Sinomeasure for Your Wastewater Projects

- Extensive experience: decades of expertise in industrial water‑ and wastewater‑treatment instrumentation.

- Full product range: from online pH/ ORP transmitters, DO sensors, turbidity transmitters to analyzers, recorders and controllers — covering all critical monitoring needs.

- Reliable performance: robust design ensures stable long‑term operation even in harsh wastewater environments.

- Customized solution support: our team can tailor instrumentation suites and configurations based on your plant layout and treatment process.

Get Started with Sinomeasure

If your facility uses — or plans to use — oxidation‑ditch or other activated‑sludge wastewater treatment processes and you aim to enhance process control, ensure compliance, and reduce manual workload, we are ready to assist. Contact us now for a free consultation, instrument configuration advice, and a customized instrumentation proposal.