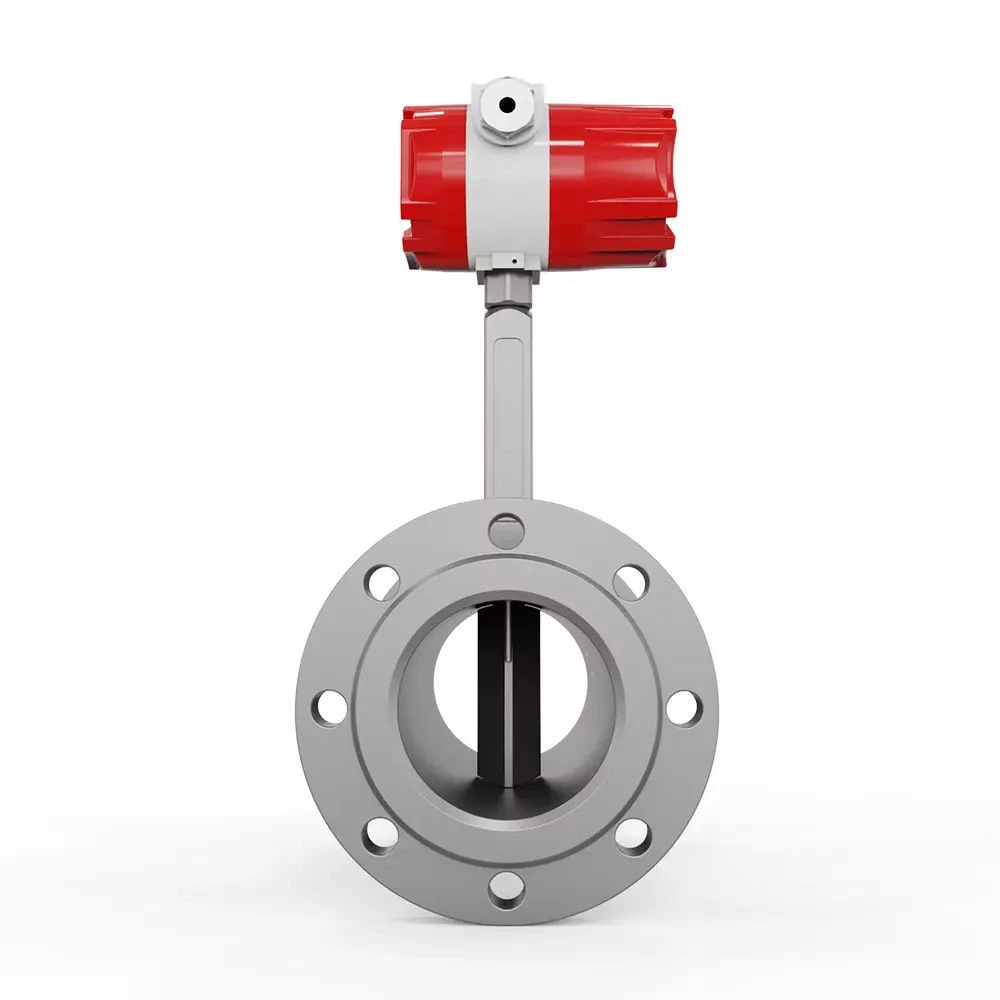

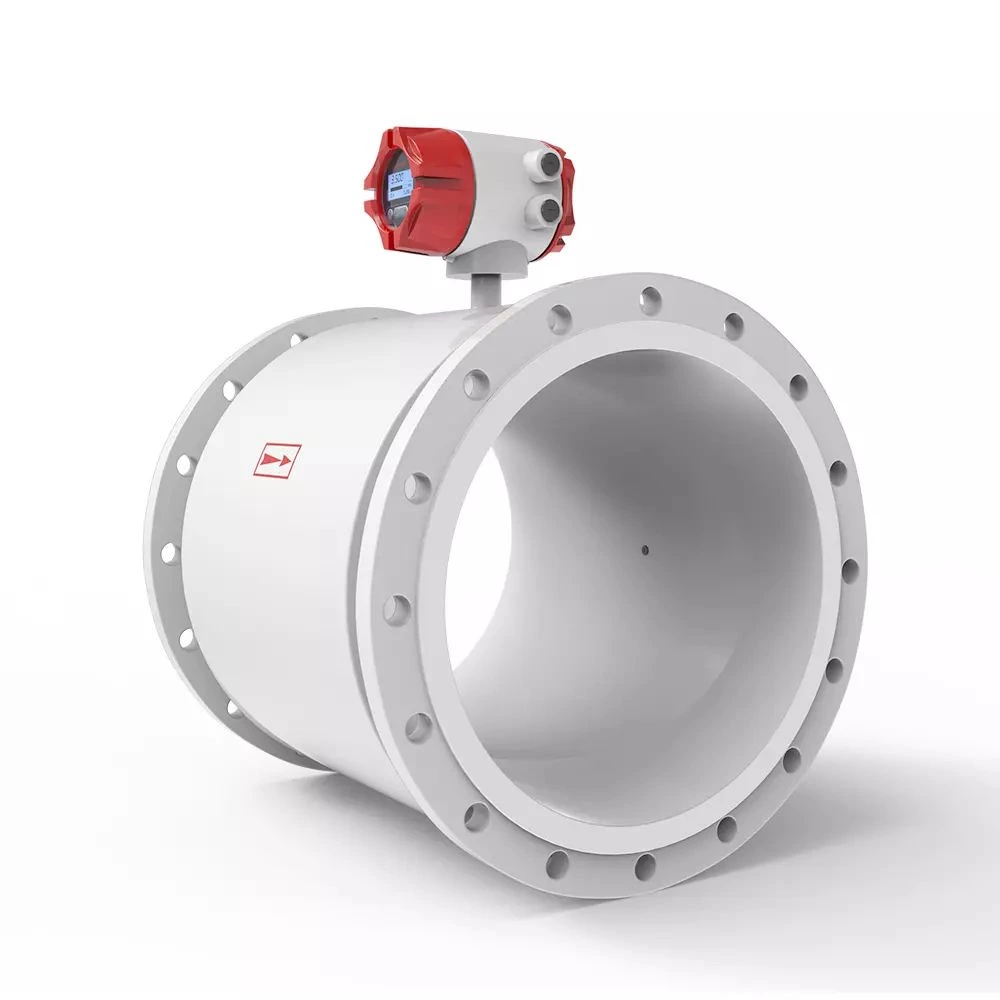

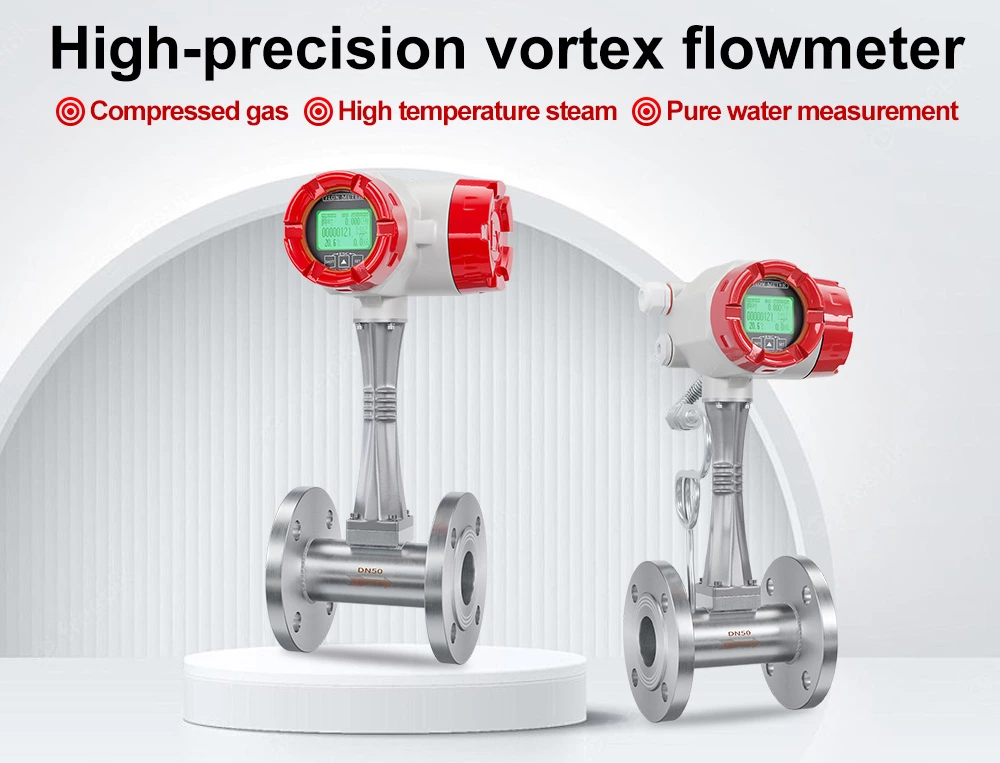

SIN-LUGB-C Intelligent anti-vibration vortex flowmeter

The vortex flomweter is a kind of velocity flow meter, which is designed based on the Karman vortex principle. It is mainly used for flow measurement of medium and fluid in industrial pipelines, such as flow control and measurement of gas, steam or liquid, and other media.

Pipe diameter: DN15-DN300

Accuracy:Flow: ±1%R,±1.5%R; plug-in type: ±2.5%R

Range ability: 1:6~1:25

Ingress protection: IP65

-

Parameter

| Nominal diameter(mm) | 15、20、25,32,40,50,65,80,100,125,150,200,250,300,(300~1000plug-in) |

| Nominal Pressure (MPa) | Clamping flange connection: DN15~DN50,≤4.0MPa; DN65~DN100,≤2.5MPa DN125 or above, ≤1.6MPa Flange connection: DN15~DN50,≤2.5MPa; DN65~DN300,≤1.6MPa |

| Use condition | Operational temperature: Std:-40~100℃,KST-M:-40~250℃, KST-HC:-40~330℃(Agreement order); Environmental temperature:-20℃~55℃,Relative humidity:5%~90%,Atmospheric pressure:86~106kPa |

| Material | Body:304(Other materials are supplied by agreement) Integrator housing: Die Casting Aluminum. |

| Allowable vibration acceleration | Piezoelectric type:0.2g |

| Accuracy | ±1%R,±1.5%R;Plug-in:±2.5%R |

| Range ability | 1:6~1:25 |

| Supply voltage | Sensor:DC +24V;transducer:DC +24V;battery-powered:3.6Vbattery |

| Output signal | Pulse output;4~20mA current、RS485(modbus- RTU agreement)and so on |

-

Introduction

The vortex flomweter is a kind of velocity flow meter, which is designed based on the Karman vortex principle. It is mainly used for flow measurement of medium and fluid in industrial pipelines, such as flow control and measurement of gas, steam or liquid, and other media.

This vortex flow meter can achieve the following functions according to the selection: measuring the temperature, pressure, instantaneous flow, and cumulative flow of medium fluid in industrial pipelines, and has pulse output, 4-20mA analog signal output, RS485 communication (Modbus RTU protocol), GPRS of Internet and other functions.

The vortex flow meter is widely used in heat supply, gas supply, chemical industry, environmental protection, metallurgy, textile, steel, pharmaceutical, paper making, drainage, and other corporations to superheat steam and saturated steam, compressed air and gas (oxygen, nitrogen, hydrogen, etc.), water and liquid (such as water, alcohol, stupid class, etc.) of the measurement and control.

-

Vortex flowmeter accuracy class

| Accuracy class | 1 | 1.5 | 2 | 2.5 | |

| Maximum impact error | qt≤q﹤qmax | ±1.0% | ±1.5% | ±2.0% | ±2.5% |

| qmin≤q﹤qt | ±2.0% | ±3.0% | ±4.0% | ±5.0% | |

| Note: The bounded flow is 0.2qmax | |||||

-

Features

1.Ability to measure flow accurately and reliably.

2.The main body of the product has no moving parts, high reliability, long-term stability, simple structure and easy maintenance;

3.The output of the sensor is pulse frequency, its frequency is linear with the actual flow rate of the measured fluid, the zero point has no drift, and the performance is very stable.

4.Various structural forms, including pipeline type, insertion type flow sensor and other forms;

5.High accuracy, the measurement accuracy of conventional liquid is ±1.0%; the measurement accuracy of gas is ±1.5%;

6.The pressure loss is small (about 1/4~1/2 of the orifice flow meter), which belongs to the energy-saving flow meter;

7.The installation method is flexible, and it can be installed horizontally, vertically or inclined at different angles according to the different process pipelines on site;

8.The circuit adopts multiple protection modes, anti-surge and strong adaptability;

9.The high-precision probe adopts the piezoelectric wafer vortex sensor, and the signal is stable.

-

Working principle

The vortex flow meter works on the principle of the generated vortex and the relation between vortex and flow by the theory of Karman and Strouhal, which specializes in the measurement of steam, gas, and liquid of lower viscosity. As shown in the below illustration, the medium flows through the bluff body, and then vortex is generated, vortices are alternately formed on both sides with opposite directions of rotation, Vortices frequency is directly proportional to medium velocity. Through the number of vortices that are measured by the sensor head, medium velocity is calculated, plus flow meter diameter and the final volume flow comes out.

Computational formula is as follows:

F=St*V/md ………………………………………………… Formula 1

Q=3600*F/K ………………………………………………… Formula 2

M=Q*ρ ……………………………………………………… Formula 3

Among Formula:

F…… Fluid flow through the bluff body generates the frequency of vortex (Unit: Hz)

St… Strouhal constant ( zero dimension )

V……Mean velocity of fluid inside the pipeline (Unit: m/s)

m……The ratio between the Lune Circulation area of the bluff body at both sides and cross-sectional area ( Unit: zero dimension )

d…… The upstream face width of the bluff body inside the vortex flow meter Unit: m )

D…… Inside diameter (ID) of vortex flow meter (Unit: m )

Q…… Instantaneous volume flow (Unit: m 3 / h )

K…… Instrument coefficient of vortex flow meter (Unit: pulses / m 3 )

M…… Instantaneous mass flow (Unit: kg/ h )

ρ……. Fluid density (Unit: kg/ m 3 )

Note: vortex flow meter "K" coefficient corresponds with one diameter, the exact ''K" value

should be calibrated in practice. Viz. one cubic meter fluid through sensor output numbers of pulse under working conditions.

Español

Español Русский

Русский