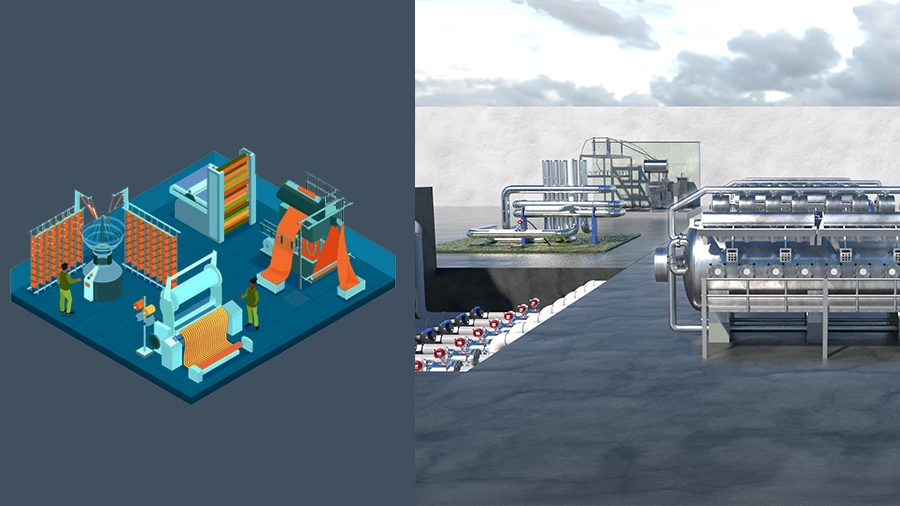

Industrial Dyeing – Steam Flow Measurement with Vortex Flowmeter

In this project, Sinomeasure deployed a vortex flowmeter — specifically a temperature- and pressure-compensated model — in both the inbound main steam pipe and multiple branch pipelines of a textile dyeing plant (Jiangsu Aokelai Dyeing Co., Ltd.). The meter provided both instantaneous and cumulative flow readings, with remote data transmission support, ensuring precise and stable steam monitoring and control. During onsite calibration and comparison, our vortex flowmeter demonstrated significantly higher accuracy than the plant’s existing flowmeters, earning strong recognition from the customer.

Project Overview

- Application Scenario: Textile dyeing plant steam supply (main and branch pipelines)

- Instruments Installed: Temperature- & pressure-compensated vortex flowmeter (plus necessary pressure transmitter for compensation)

- Purpose: Accurate measurement and monitoring of steam flow (both instantaneous and cumulative) to ensure stable dyeing process control and efficient steam usage

- Outcome: Improved measurement accuracy, enhanced steam usage stability, better production consistency, and reliable remote data logging for process management

Why Vortex Flowmeter Works Well for Textile Dyeing Steam Supply

Textile dyeing processes demand precise control of steam flow to ensure consistent dyeing temperature, pressure and process repeatability. By using a temperature- & pressure-compensated vortex flowmeter, plant operators gain: - High-accuracy instantaneous flow measurement and accurate cumulative flow totals — essential for steam usage accounting and cost control. - Stable, reliable performance even under varying steam pressure and temperature conditions. - Remote data transmission capabilities for integration into PLC/SCADA systems, enabling automated monitoring, logging and process control. - Enhanced process repeatability and dyeing quality due to precise, consistent steam supply.

Recommended Sinomeasure Instrumentation Package for Similar Applications

For textile dyeing or other industrial applications requiring accurate steam (or other fluid/gas) flow measurement and control, we recommend:

- Temperature- & pressure-compensated vortex flowmeter — for accurate instantaneous & cumulative flow data under varying steam conditions.

- Pressure (and/or temperature) transmitter — to provide compensation inputs, ensuring measurement accuracy across operational conditions.

- Signal output & data-communication module — for remote data transmission and integration with factory automation / SCADA systems.

- Optional: Flow-control valves + process controller — for closed-loop control based on real-time flow data, enabling automated steam dosing or load control.

Why Choose Sinomeasure for Industrial Steam & Process Flow Measurement

- Proven field performance — our vortex flowmeters have demonstrated superior accuracy and reliability in demanding industrial dyeing environments.

- Full-featured instrumentation — with temperature/pressure compensation, remote output and cumulative flow functions, satisfying diverse industrial control needs.

- Professional support — on-site commissioning, calibration, and debugging ensure our instruments integrate smoothly into existing process systems.

- Scalable solution — suitable not only for steam measurement, but also for other fluids and gases in textile, chemical, energy and general manufacturing sectors.

Partner with Sinomeasure for Your Industrial Flow Measurement Needs

If your facility involves textile dyeing, chemical processing, or other industrial steam/fluid applications and requires precise flow measurement or consumption monitoring — we are ready to support you. Contact us now for consultation, instrument configuration advice, and a tailored instrumentation package.