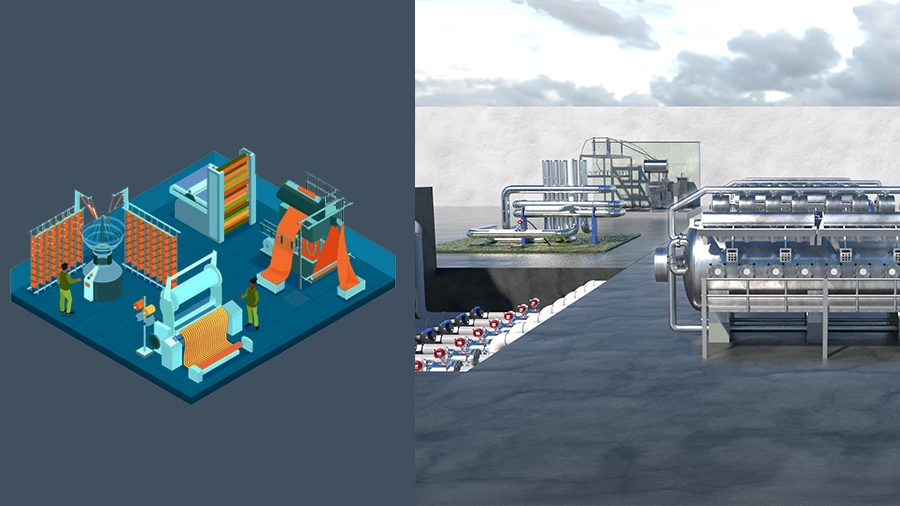

Food Processing Wastewater Treatment

Project Overview

Food processing wastewater typically contains high concentrations of organic matter and a large amount of suspended solids. This case applies electromagnetic flowmeters, online pH meters and ultrasonic level transmitters to monitor and support biological wastewater treatment processes.

Application Scenario

- Industry: Food processing (sugar, brewing, meat, dairy and other food production)

- Installed instruments: Electromagnetic flowmeter, online pH meter, ultrasonic level transmitter

- Purpose: Real-time monitoring of flow, pH and tank levels to optimize biological treatment and dosing

Typical Wastewater Characteristics

- High organic load (e.g., sugars, proteins, fats) leading to elevated BOD/COD.

- Large amounts of suspended solids (peels, fragments, meat particles, feathers) and colloids.

- Presence of fats, oils and greases (FOG) which may cause flotation and pipe fouling.

- When animal-derived materials are present: potential pathogens requiring careful handling and disinfection.

Key Technical Challenges

- Equipment fouling from fats, proteins and suspended solids — requires pretreatment (screening, grit removal, fat traps).

- Large variability in influent quality depending on production schedules and raw materials.

- Need for stable biological conditions (pH, dissolved oxygen) to maintain treatment efficiency.

Recommended Treatment Approaches

For most food industry wastewaters, biological treatment is effective due to high biodegradability. Depending on load and discharge requirements, consider:

- Primary screening and sedimentation to remove large solids.

- Fat, oil and grease removal (FOG separation) where required.

- Biological treatment options: aeration tanks, sequencing batch reactors (SBRs), or combined anaerobic–aerobic systems for high-strength wastewater.

- Disinfection when animal-derived wastewater introduces pathogen risks.

Instrument Role & Advantages

Accurate, continuous measurement enables optimized control and compliance:

- Electromagnetic flowmeter: Stable flow monitoring for influent/effluent and chemical dosing control.

- Online pH meter: Real-time pH monitoring for neutralization and biological stability.

- Ultrasonic level transmitter: Tank and sump level control for pumps, return activated sludge (RAS) and sludge handling.

Benefits from Sino-measure Instruments

- Continuous monitoring reduces manual sampling and improves traceability.

- Early detection of process deviations (e.g., pH swings) facilitates rapid corrective action.

- Improved effluent stability and regulatory compliance through tighter process control.

Project Summary

Food processing wastewater is variable but generally biodegradable. Through proper pretreatment, selection of appropriate biological processes, and deployment of reliable instrumentation (flow, pH, level), treatment facilities can achieve consistent, compliant effluent while minimizing manual workload and operational risk.

Related Products

Ready to optimize your industries process?

Contact our experts for consultation, instrument configuration and on-site support.